Types of Machining Centers

Trevisan Machine Tool sets the industry standard for high-performance milling and turning solutions. Since 1963, we have designed and built specialized equipment to solve each customer’s most demanding and complicated applications. We have grown to offer a complete line of integrated contour head U-axis machining centers while providing custom-engineered solutions for the most challenging projects.

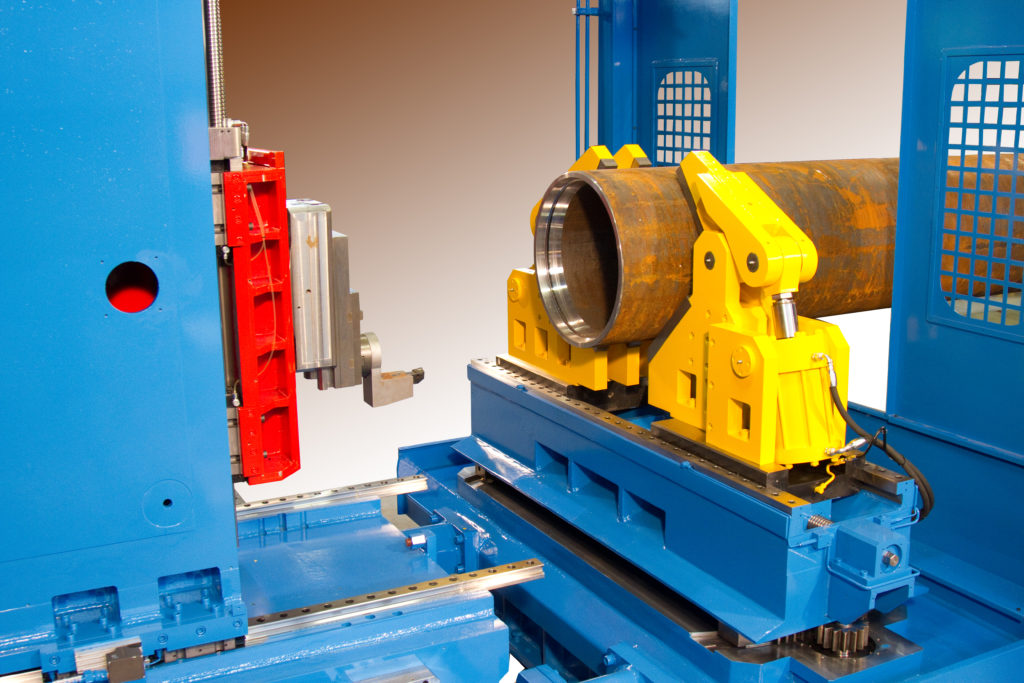

The Trevisan concept involves holding a workpiece stationary and rotating the tools around it. Besides performing complex milling operations, the process can also complete turning operations. Operators can machine heavy or odd-shaped parts on all sides without an additional setup or handling. Less material handling and minimal setups result in fewer operator errors, tighter tolerances, safer working conditions and faster cycle times.

Universal Automated Machining Center Solutions

One of the most significant benefits of our equipment is performing multitasking machining for valve components and other parts. Our machine solutions stand out from similar equipment because they eliminate changeovers, reduce cycle time, increase product quality and minimize handling.

Our comprehensive equipment lineup includes:

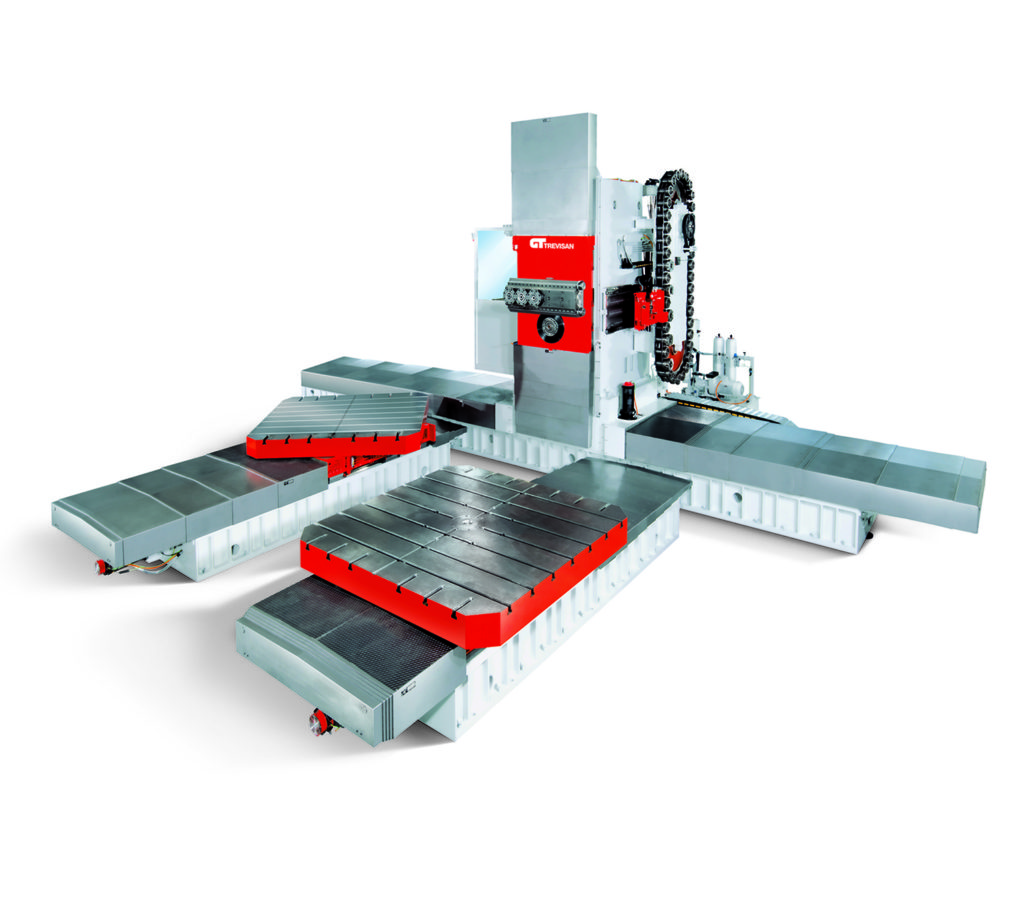

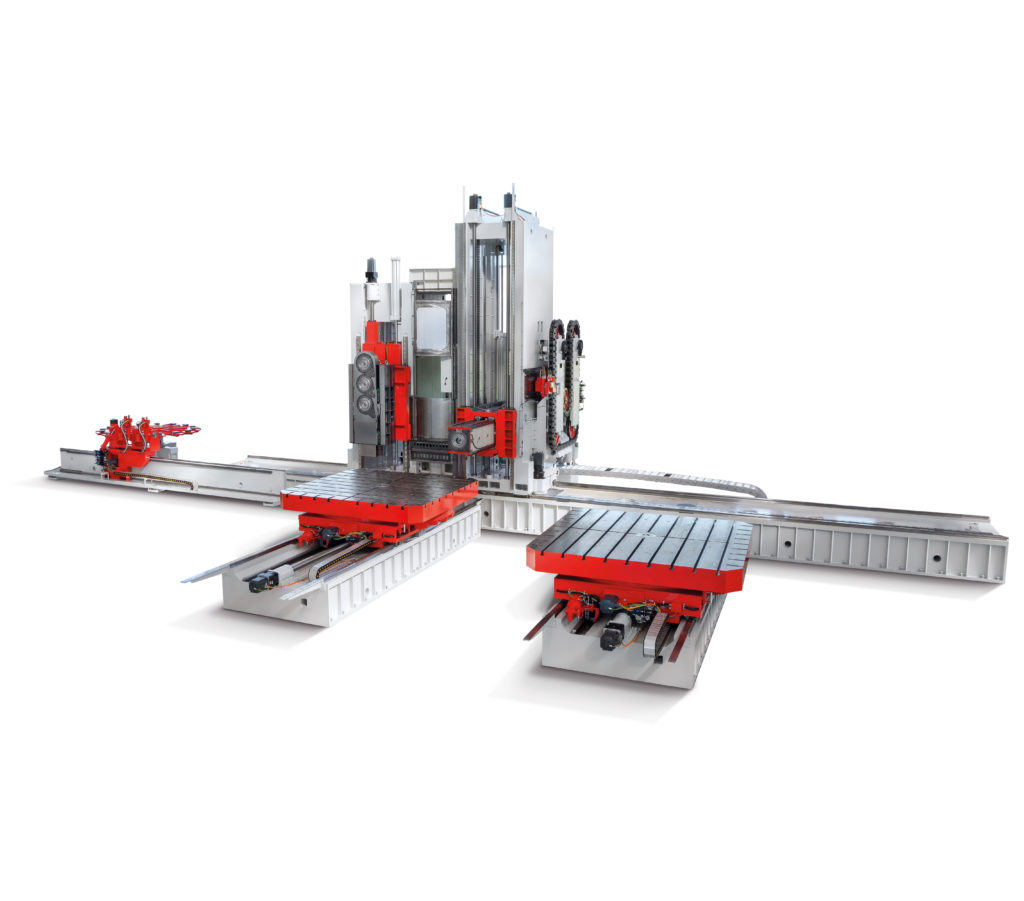

INTEGRATED U-AXIS MACHINING CENTERS

Our horizontal machining centers combine the benefits of stationary-part fabrication with the advantages of rotating-part machining. When performing rotating-part machining on a vertical lathe, the cutting speed is restricted because of the chuck’s diameter, resulting in significantly slower production times.

To achieve a more efficient solution, Trevisan facing machining centers utilize a specially designed gearbox, a patented tool holder and a facing head that varies depending on the model and machining requirements. These features ensure maximum torque and power with higher RPMs for optimal cutting production.

Our horizontal machining center lineup includes the following models:

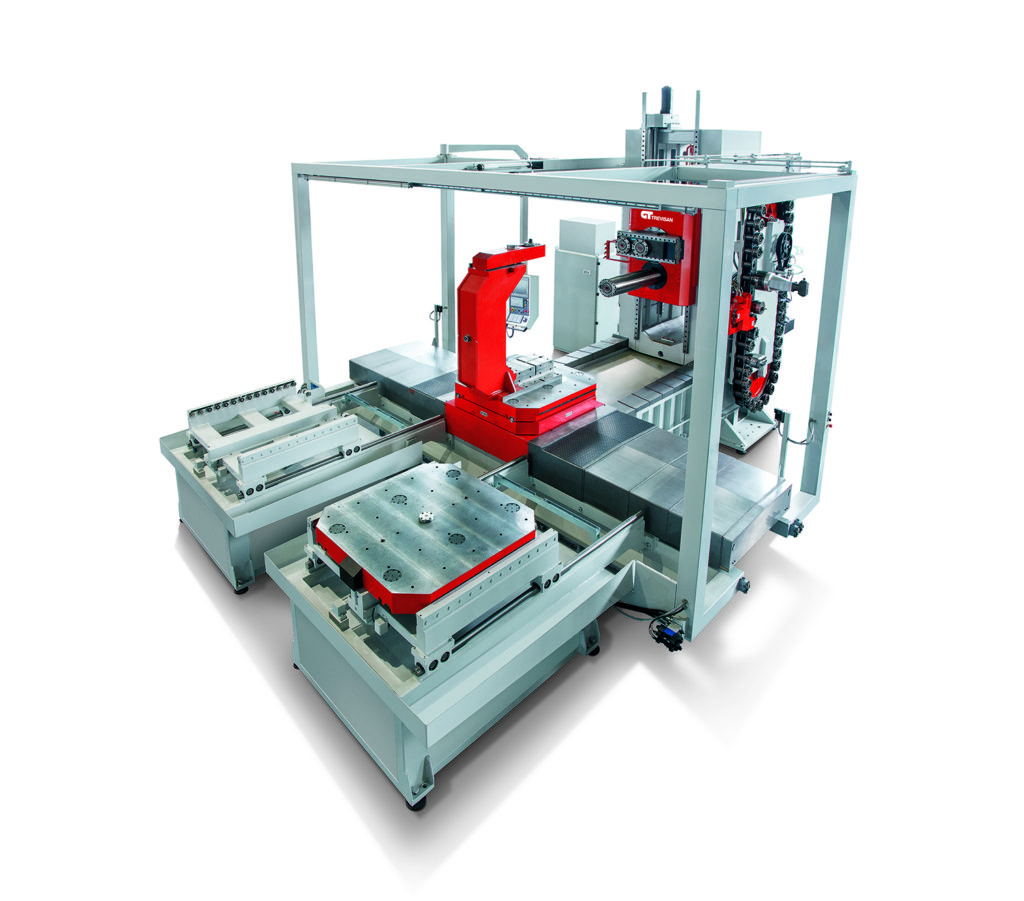

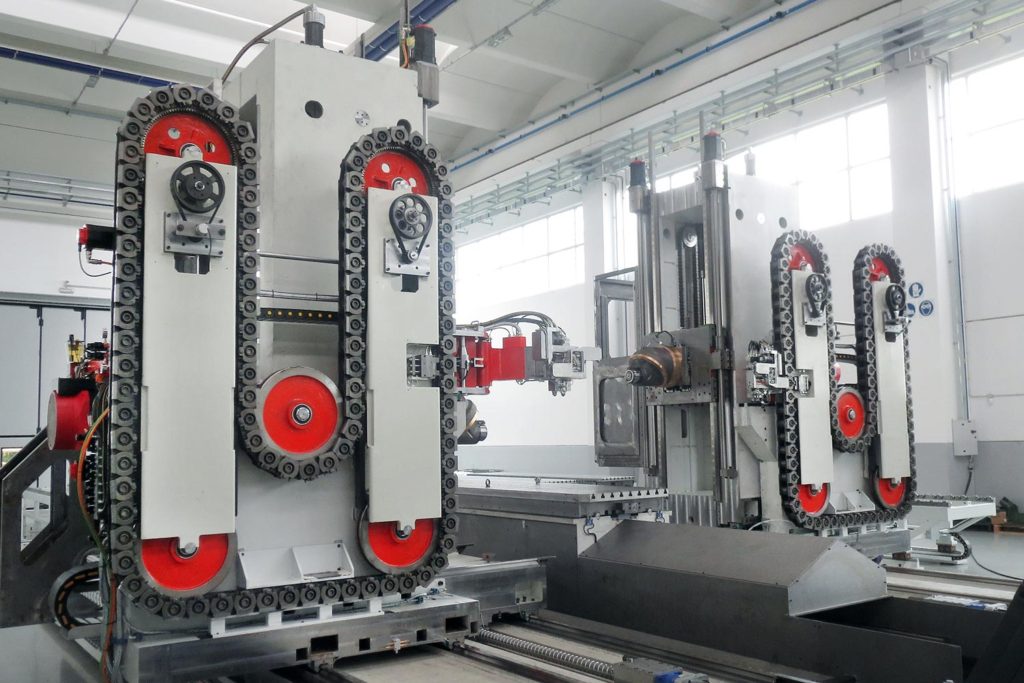

MODULE EQUIPE UNITS

Trevisan Module Equipe machines are turret modules that are fully adaptable to meet your product needs. These modules have six position turrets configurable with any combination of contour heads, mill-drill spindles, multi-spindle drills or tapping heads. Combining several modules in the same machine system offers limitless customized solutions that can machine multiple sides of a part simultaneously for faster cycle times.

HIGH SPEED MACHINING CENTERS

Vertical turning line machines from Trevisan feature a fully automated parts transfer system with stamping capabilities, combining several high-speed vertical lathes and drilling stations in a single unit. With the added stations, the machine can work on multiple parts simultaneously to reduce cycle time.

Trevisan offers multiple standard machine sizes that are highly customizable to enhance product output and quality further.

SPECIALIZED MACHINING

Girolamo Trevisan started Trevisan Machine Tool by building specialized custom machines in 1963. Today, Trevisan still carries on this passion to engineer custom machines to meet the customer’s ever-changing needs.

We build many of these customized machines from our proven technology of the standard machining lines. They are then modified and reconfigured to meet the customer requirements throughout an ever-growing number of industries worldwide.

Contact Trevisan to Learn More About Our High-Speed, Universal Machining Centers

If you want to learn more about how our equipment can improve the efficiency and quality of your machining operation, the experts at Trevisan Machine Tool can guide you. Contact us today to request a quote or additional technical information.