WELCOME TO

Trevisan Machine Tool

With over 60 years of experience, Trevisan Machine Tool offers a complete line of integrated U-axis contour head machining centers with various engineered solutions for the toughest and most challenging manufacturing projects.

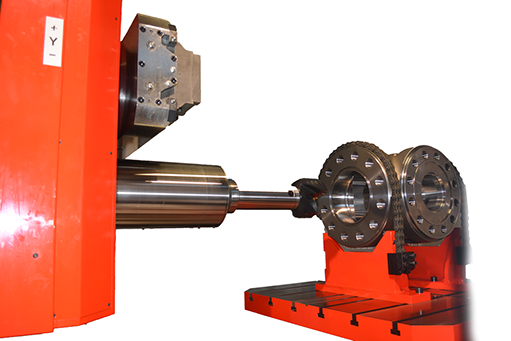

The Trevisan concept involves holding a workpiece stationary while rotating the tools around it, enabling complex milling and turning operations without additional handling or re-fixturing.

The Trevisan Difference

As production and quality requirements become more demanding, Trevisan’s decades of experience, technical knowledge and engineering expertise help customers meet their unique challenges. Trevisan offers a complete lineup of horizontal machining centers with turning capabilities up to 3 meters in diameter, plus a comprehensive range of customized solutions for the fabrication requirements of each customer.

Trevisan is a pioneer in contour head development and has specialized in horizontal machining centers for years. Whether your goal is reducing cycle time, eliminating changeover time, improving quality or minimizing floor space, Trevisan has the solution for you. Several features that enable our equipment to produce higher-quality components include:

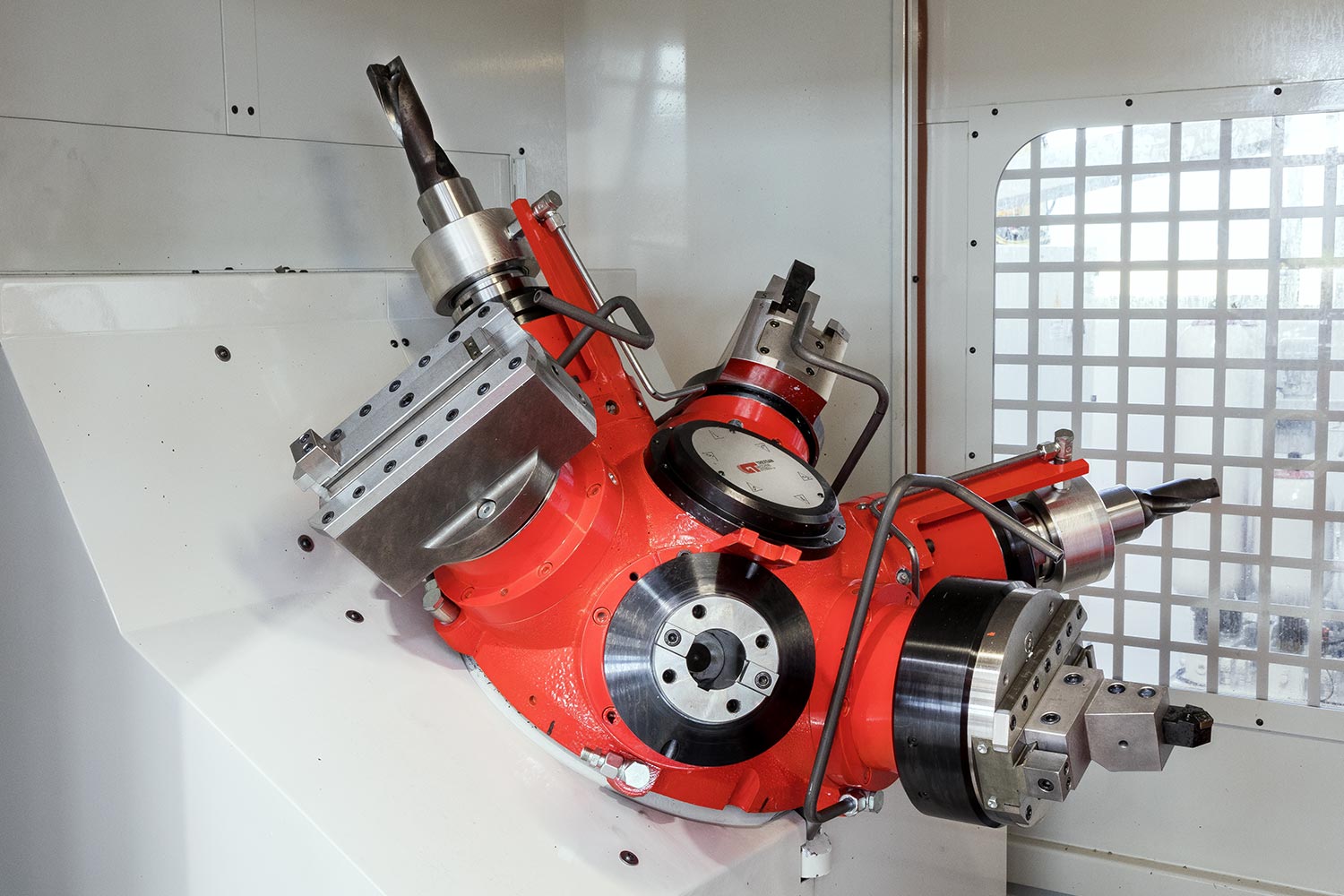

DUAL SPINDLE DESIGN

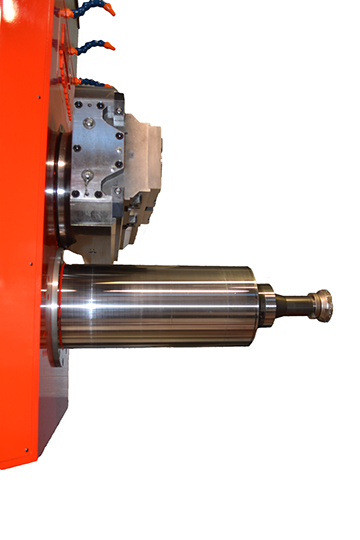

Trevisan’s horizontal machining centers have a unique head design that contains two spindles — one for the spindle quill and another for the U-axis facing head. With milling and turning capabilities, the spindle head can complete the entire machining process with one setup.

Additional benefits include:

- CNC control using FANUC motors and controls.

- Turning, boring, facing, back-facing, milling, tapping, drilling and more all on one machine.

- Significant reduction of a part’s total production time.

- Tools are changed directly from the magazine to the contour head for better convenience.

- With our integrated contouring head in place, stoppages or manual intervention are not required to switch from milling to turning.

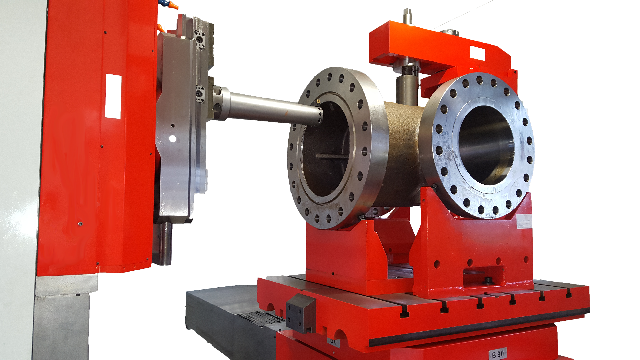

STATIONARY PART MACHINING

By holding the workpiece stationary and moving the machine around the part, Trevisan milling centers can machine a broader range of products than conventional equipment. This configuration lets operators turn large workpieces without rotating them.

This benefit provides significantly faster cutting speeds over equipment that requires parts rotation. With a fully programmable B-axis table and multi-pallet setup, the machine can produce many parts from start to finish in a single pass. Part changeover occurs during operation, reducing or eliminating changeover setup times. Combined with the dual spindle design, this feature minimizes cycle time while increasing production and profit.

Our valuable machining capabilities include:

- Offset turning operations such as boring on fluid ends.

- Unbalanced parts such as valves, pump housing and rock bits.

- Multiple turning features in the same setup on gearbox housings or manifolds

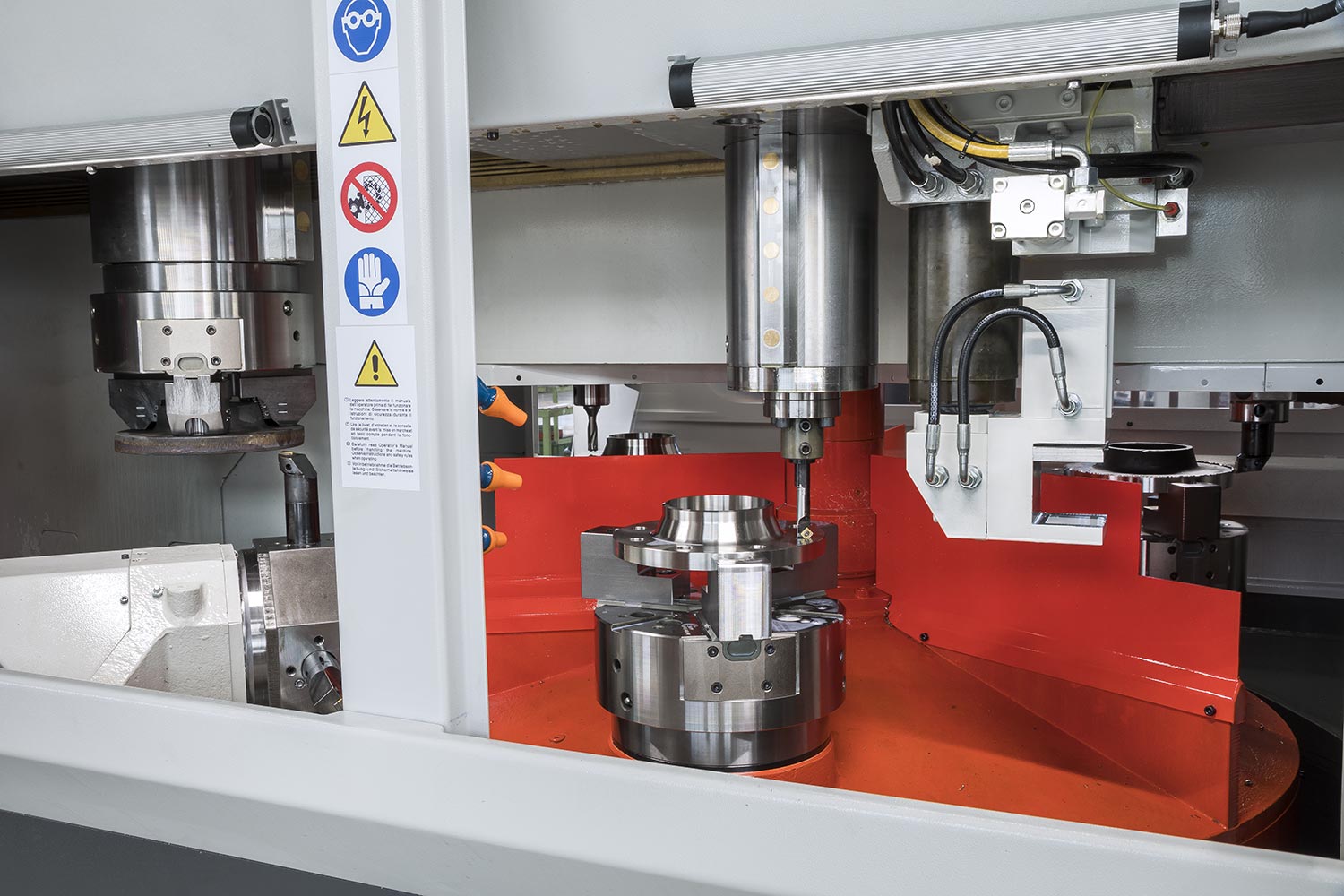

INTEGRATED U AXIS FACING HEAD

Integrating the facing head on a different spindle with a separate quill gives the machining center an entirely new dimension, providing all the benefits of a lathe machine without the disadvantages.

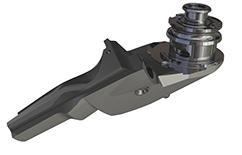

OFF-CENTER & UNBALANCED TURNING

Implementing a facing head enables a horizontal machining center to bore offset diameters or turn at any point on the part without the unbalanced conditions of traditional turning.

For a machine to turn with only a milling head, you must purchase an aftermarket facing head or utilize complex manipulation methods that can cause wear and tear.

The integrated facing head allows our machines to produce items like valves, axle housings, fluid ends, pump housings, gearboxes and other parts much more efficiently than other processes.

HEAVY-DUTY SPINDLE QUILL

The machining center’s second spindle contains a quill for milling, tapping and drilling. This oversized, heavy-duty spindle can accommodate the most challenging milling operations while producing fast metal removal rates.

- Coolant through the spindle to the tooltip

- An optional U-axis drive for tool-changeable angles and facing heads.

The Trevisan Ram Series machining centers feature an extendable, large-diameter W-axis quill to enable a more rigid reach.

The NEW DS600/200c ram has two separate 100-horsepower direct drive spindle motors — one for the contour head and another for the quill.

TREVISAN SOLUTIONS

Trevisan has been in the business of designing and developing specialized machines for the unique needs of each customer. We use this experience and knowledge daily to create new ideas and improve existing concepts.

When you purchase a Trevisan machine, we consider it a partnership. Our team will work with you to design and recommend various options to create the most advantageous solution for your product needs.

More advantages of our horizontal milling centers include the following:

- Extended X, Y and Z axes.

- Multiple pallet options, including systems for larger pallet sizes and three or more pallets.

- Trevisan fixturing.

- Changeable angle and facing heads for the spindle quill.

- Coolant through the spindle to the tooltip on the quill and the facing head.

- Turnkey solutions.

- Tested and proven technology.

- Multi-angle milling head attachments.

CUSTOM MACHINE TOOL BUILDERS

Trevisan stands out from similar CNC equipment manufacturers, distributors and dealers because of our extensive experience, superior customer support and spare parts availability. We have decades of expertise in building custom CNC machines when customers cannot find a standard solution for their products.

Choose Trevisan for High-Performance Horizontal Machining Centers

If you’re looking for a custom machine tool builder that manufactures superior equipment for high-volume machining operations, Trevisan Machine Tool is a perfect choice. Contact us today to learn more about how our equipment can benefit your business.