Heavy-Duty Machining Solutions

Heavy-duty horizontal milling centers from Trevisan Machine Tool have been at the forefront of machining technology for years. Our milling centers are crucial in machining operations because they possess the strength and capability to handle demanding tasks that traditional lathes and heavy-duty milling machines cannot accommodate.

The primary benefit of Trevisan’s heavy-duty milling centers lies in their ability to remove large amounts of material with fewer passes. These durable metal cutting CNC machines are capable of providing decades of reliable use. Our solutions can handle larger workpieces without sacrificing quality, with the added capability of creating complex and intricate components.

Types of Heavy-Duty Machining Centers We Offer

Our precision machining equipment features all the benefits of a conventional heavy-duty milling machine or lathe with increased versatility and production efficiency. Horizontal milling centers from Trevisan Machine Tool provide rigidity and stability, ensuring accuracy and repeatability in machining processes. They come equipped with advanced control systems and automatic tool changers (ATCs) that enable precise positioning and movement of the cutting tools, resulting in accurate and consistent machining results.

More importantly, our heavy-duty milling centers can perform a comprehensive range of machining tasks in a single setup, from turning and milling to tapping, contouring, drilling, facing and boring. Our lineup of heavy-duty machining centers includes:

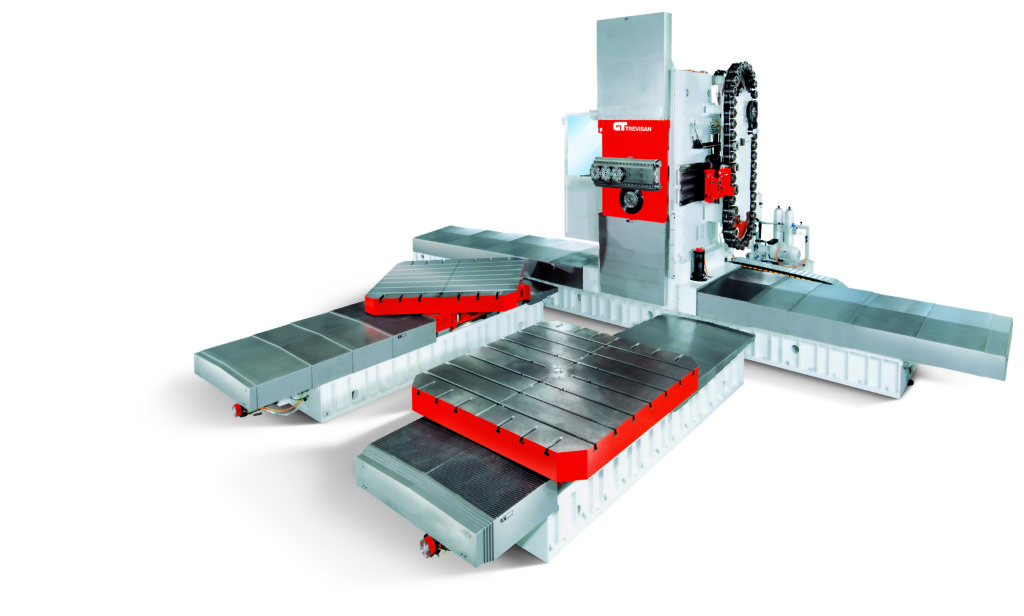

- DS600/RAM: Our DS600/RAM milling center with two 100-horsepower spindle motors offers superior rigidity and power for your most challenging requirements. The machine’s size is perfect for handling various-sized jobs with turning diameters up to 900 millimeters.

- DS900/300C: Trevisan’s DS900/300C machine is ideal for medium to large, heavy-duty jobs requiring turning diameters up to 1,500 millimeters. The facing head offers all the features of a conventional CNC heavy-duty lathe, including single-point-threading, consistent surface speed and contouring capabilities.

- DS1200/450C: Our DS1200/450C milling center is ideal for large workpieces with turning diameters up to 2,000 millimeters. Besides offering a CNC lathe’s benefits, this machine is excellent for heavy milling or drilling. The 250-millimeter contour head adds versatility with the ability to machine smaller parts when needed.

- DS1500/450C: Trevisan’s DS1500/450C is perfect for machining large parts requiring multiple tools for milling and turning with turning diameters up to 2,500 millimeters. The machine changes the tools from the magazine to the quill spindle or any of the contour head’s three pocket positions.

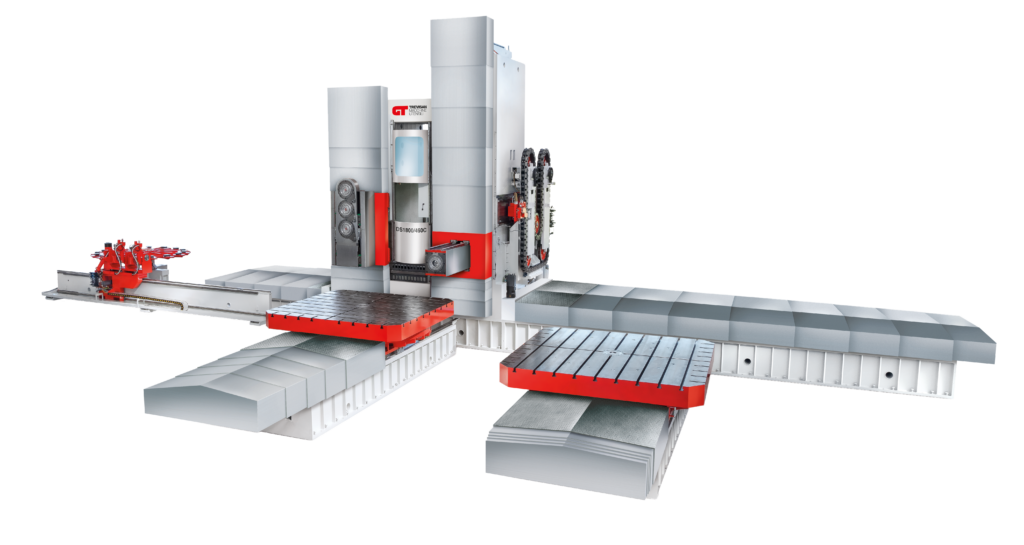

- DS1800/460C: Our DS1800/460C colossus-series milling center is our heaviest-duty machine. The double-column assembly features one column for milling and another for turning. The contour head offers a 3,000-millimeter turning capacity, while the RAM features a 99-tool magazine that can handle large tools like milling heads, set angle heads and high-torque facing heads.

Contact Us (sidebar)

"*" indicates required fields

Advantages of Choosing Trevisan Machine Tool

As demands for increased production capacity and higher product quality become more prevalent throughout the machining industry, our solutions help customers overcome challenges from their unique applications. Our team has decades of experience assisting customers in choosing the most practical and efficient equipment solutions.

Trevisan’s lineup of heavy-duty milling centers stands apart from equipment offered by competitors because we provide several machines with various turning diameters and facing head sizes that produce higher-quality components. We are a United States-based company offering personalized local support with an extensive inventory of ready-to-ship replacement parts.

Contact Us Today to Discover More

If you want to learn more about how our heavy-duty machining centers can benefit your operation, the professionals at Trevisan Machine Tool can guide you. In addition to our standard milling centers for precision CNC heavy equipment machining, we offer customized solutions tailored to each customer’s requirements. Contact us online today to request a quote or obtain additional technical information.