Vertical Machining Center

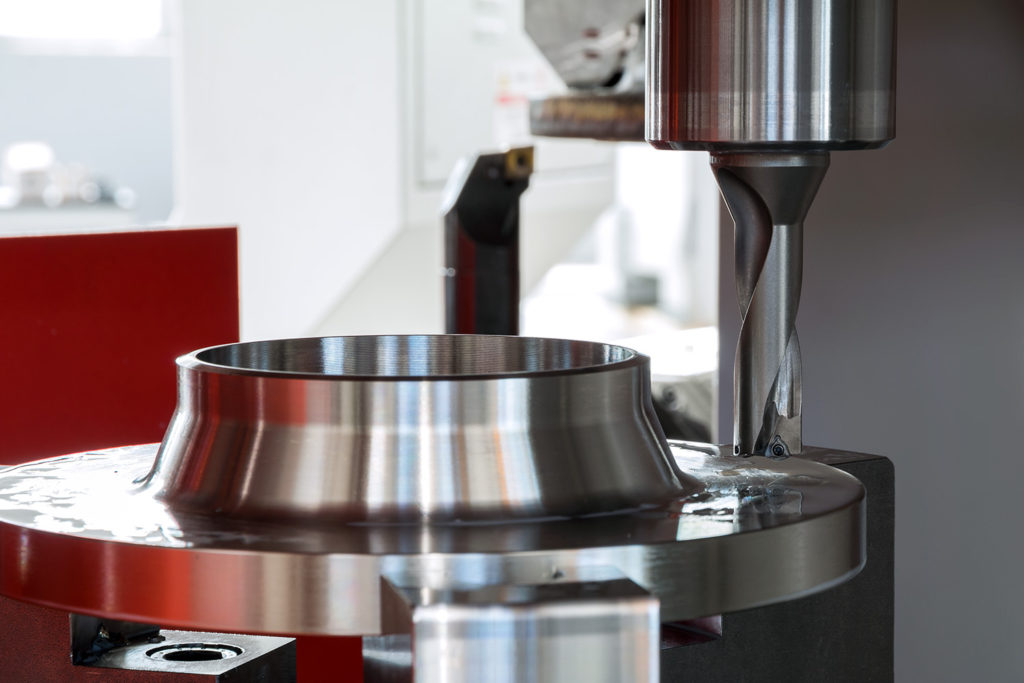

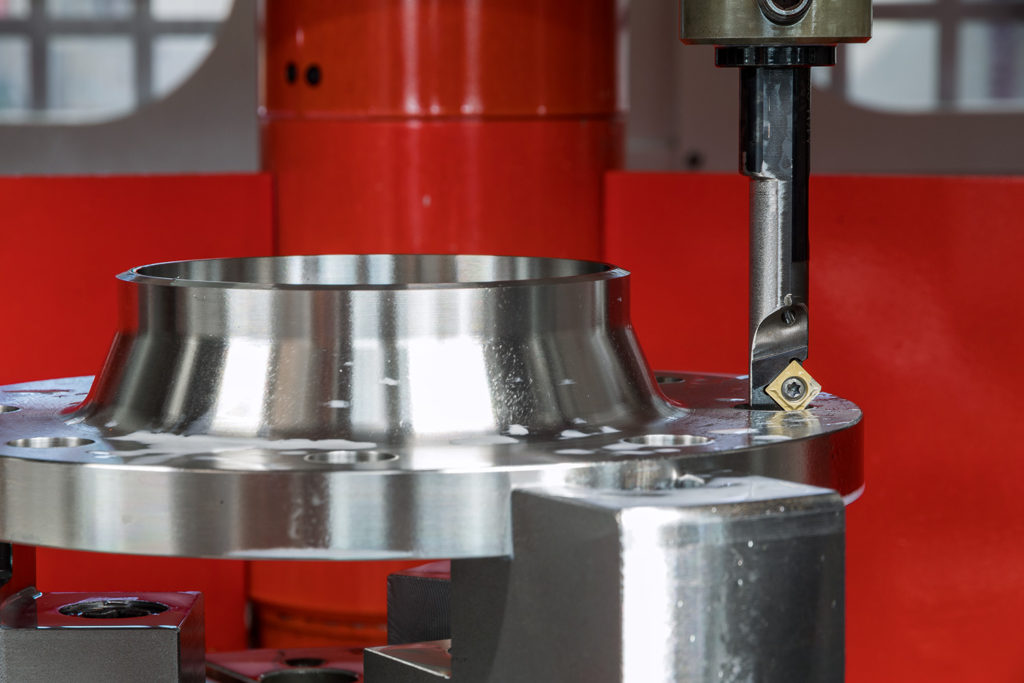

Vertical machining centers operate by holding a workpiece vertically, rotating it around a cutting tool attached to a spindle and removing material to shape a finished part. The vertical orientation enables gravity to help secure the workpiece and provides enhanced stability when machining parts, increasing accuracy and precision for many product types. These machines have multiple axes that enable the cutting tools to create complex shapes and geometries.

Trevisan Machine Tool offers industry-best vertical machining centers with features that enable the spindle to pick up the workpiece and move it between stations during machining, allowing continuous operation without manual intervention. These vertical machining centers are only one of the many high-performance CNC machining equipment solutions we offer to help customers improve product quality and maximize operational efficiency.

Our experienced staff has decades of expertise in assisting customers in choosing the most practical and efficient machine options for the unique needs of their operations.

Pick-Up Multi-Station Turning Centers

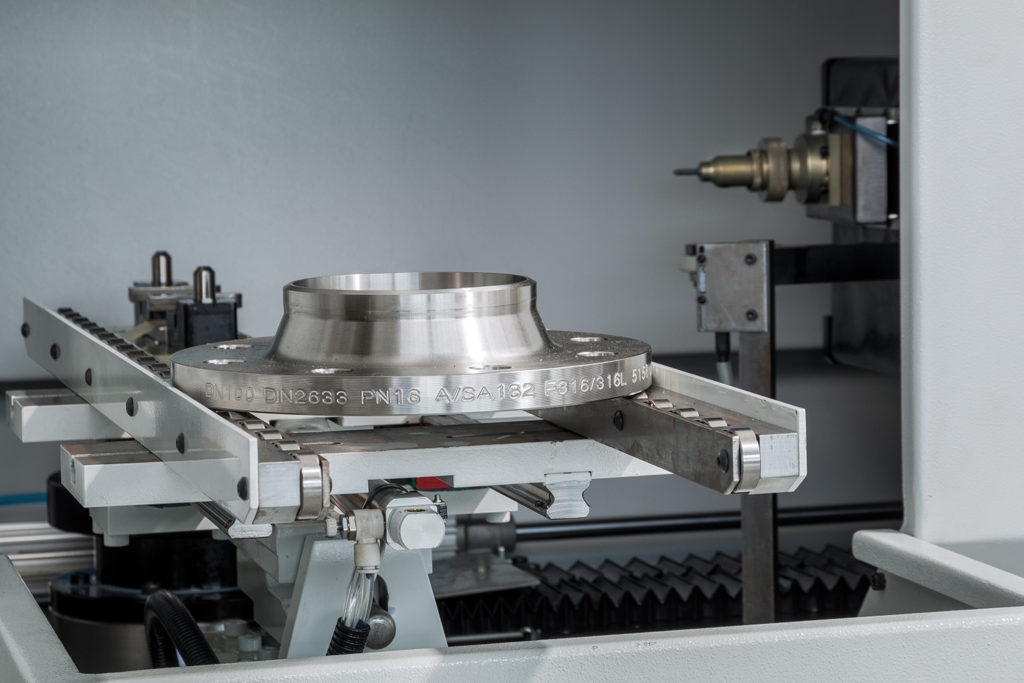

Trevisan Machine Tool’s vertical turning lines combine multiple vertical turning lathe machines, drilling and tapping stations, an automated parts transfer system and stamping capabilities in one compact piece of equipment. These features allow the operator to place the part in the loading area and unload it when finished, increasing machine efficiency by cutting down on multiple machine transfers.

In addition, having multiple stations allows the machine to work on several parts simultaneously to decrease cycle time. The main products for these machines are flanges, but they can also machine parts like valves, pumps and similar components.

Trevisan’s pick-up turning lines are available in nine spindle sizes ranging from 170 to 1,300 millimeters. In addition, these lines are customizable with horizontal operating units and tool changer magazines to optimize production.

The specific functions of our vertical turning centers include:

- Loading the pieces

- Turning the bottom and outside

- Turning the top and inside

- Drilling

- Chamfering

- Stamping and unloading

Contact Us (sidebar)

"*" indicates required fields

LOADING THE PIECES

TURNING THE BOTTOM & OUTSIDE

TURNING THE TOP & INSIDE

DRILLING

CHAMFERING

STAMPING & UNLOADING

Advantages of Selecting Trevisan Machine Tool for Vertical CNC Machining Centers

When you choose Trevisan for your machining needs, you’ll receive a solution that outperforms equipment from other vertical machining center manufacturers. Specific benefits of our pick-up multi-station turning centers include:

- Improved productivity: The multi-spindle pick-up feature and fast operating speeds help reduce lost efficiency and bottlenecks between machine cycles.

- Increased stability and accuracy: The vertical orientation helps enhance workpiece stability for many jobs, increasing accuracy and precision during machining.

- Versatility: Vertical pick-up machining centers have multiple axes of movement, enabling them to perform additional tasks like drilling, tapping and stamping.

- Cost-efficiency: Automated features help reduce the need for manual labor associated with loading and transferring parts between cycles.

Contact Us Today for More Information

If you’re looking for a reputable machine tool builder offering one of the industry’s most comprehensive metal-cutting machining equipment selections, Trevisan Machine Tool is the answer. Since 1963, we’ve helped customers solve their most demanding machining challenges by offering solutions that maximize efficiency and finished product quality. Contact us online today with questions or to request a quote.