Automotive CNC Machines

In 2022, automotive manufacturers around the world produced about 85 million vehicles. As the industry continues to expand, automotive factories seek more efficient ways to keep up with this evergrowing demand. Computer-programmed production methods are already common across the automotive sector, but they are only growing in popularity as these manufacturers strive to increase their product output.

CNC machining offers the automotive sector an effective way to streamline its production processes without requiring more manual labor. Here at Trevisan Machine Tool, we provide advanced CNC solutions for businesses across a range of industries, including automotive companies.

Our Automotive Machining Centers

At Trevisan Machine Tool, our CNC machining centers have unique features that simplify the overall manufacturing process for automotive production companies. Our technology can successfully perform milling and turning operations in a single setup, which results in less material handling. Our dual-spindle design and integrated U-axis machining centers offer manufacturers a range of benefits, including:

Few manufacturing processes can achieve the same tight tolerances and consistency as CNC machining. These manufacturing solutions dramatically reduce the instances of slowdowns due to human error.

Automotive manufacturers require consistency to maintain their quality standards. Since CNC machines use computer-programmed commands, they make parts the same way every time.

These CNC systems drastically increase productivity when replacing human effort. When automotive companies incorporate CNC machining into their processes, they will see faster production times and a reduction in the need for manual labor.

Thanks to the precision, consistency and productivity of CNC machines, manufacturers can save time and money by realizing less material waste and improved output.

Contact Us (sidebar)

"*" indicates required fields

Common Automotive Machining Applications

From engine block production to electric motor stator housing machining, the automotive manufacturing sector relies on CNC technology to carry out its operations. Vehicle production companies often use computer-programmed machines to create parts such as:

Gearboxes

Gearboxes are complex systems made from intricate parts, each playing a specific role in the vehicle's transmission system. Gearbox manufacturing machines cut each component to size, ensuring a perfect fit inside the transmission system so that it functions smoothly. Computerized machining solutions are ideal for achieving this type of precision.

Engine Blocks

Engine blocks must withstand harsh conditions since they house the cylinders where combustion takes place. Automotive manufacturers need thousands of these components, and each one must meet industry safety standards. Our CNC engine block machining centers can keep up with this high demand, as they perform multiple operations without additional setups.

Electric Motor Stator Housing

Electric vehicles are becoming more popular, with approximately 10.2 million units sold worldwide in 2022 alone, and each of these units requires a motor stator housing to function. Stator housings have thin walls with multiple ribs outside the structure. Our equipment's dual-spindle design can be used for rotating and milling operations, making it ideal for machining stator housings.

Axles

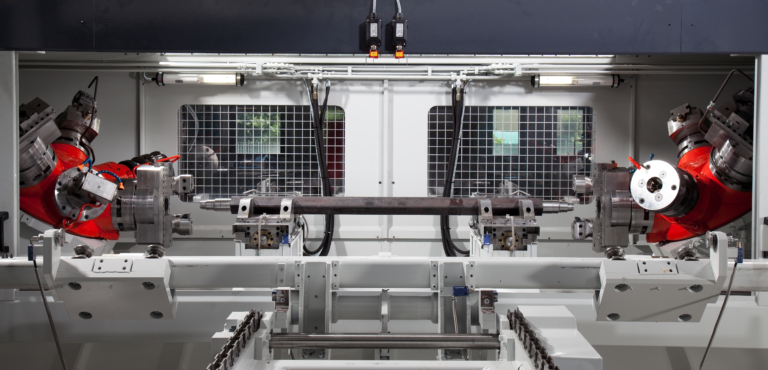

Axles are an essential component in any vehicle, and producing large vehicle axles requires roughing and finishing capabilities to work efficiently and meet industry standards. Trevisan's custom Axle End Finish Machine was designed for machining axle ends and housings. With sufficiently long workpieces, operators can set multiple Modulo Equipe units to perform tasks on each end without interfering with each other, increasing efficiency.

Learn More About Our Automotive CNC Machining Equipment

At Trevisan Machine Tool, we have a sizable inventory of CNC machining centers suitable for manufacturing automotive components. Browse our video gallery to see these state-of-the-art devices in motion. You can also contact us online to learn more about our CNC equipment and how it can benefit your automotive company.