5-AXIS MACHINING CENTERS

A 5-axis CNC machine is the ideal solution when you need unconventional parts. It moves the workpiece and cutting tool simultaneously while the axes rotate around it, creating intricate geometrical parts. Depending on the configuration, the additional fifth axis rotates left or right around the x, y or z-axis. This achieves a greater dynamic work offset for enhanced cutting accuracy and precision.

Trevisan Machine Tool offers CNC machinery for numerous industry applications, including 5-axis for complex designs.

5-Axis machining Common applications

Five-axis machines allow for access to a workpiece from five directions in a single action, saving time. Consequently, operators do not have to reposition the workpiece manually after completing an action each time.

Due to their elaborate functionality and features, 5-axis machines are used in complex applications in the following industries:

- Automotive engineering: Engineering and other automotive parts, including engines, housings and body panels.

- Aerospace and defense: Includes air and water parts for military use, such as aircraft and submarines.

- Medical manufacturing: Producing medical instruments and devices for hospitals and laboratories.

- Energy: Components for power stations, including solar panels for commercial and residential properties.

- Industrial: Machining centers manufacture heavy-duty equipment such as hydraulic breakers and excavators. Other parts include impellers, industrial pumps, bearing and gear housings and gearboxes.

ABOUT OUR MACHINING CENTERS

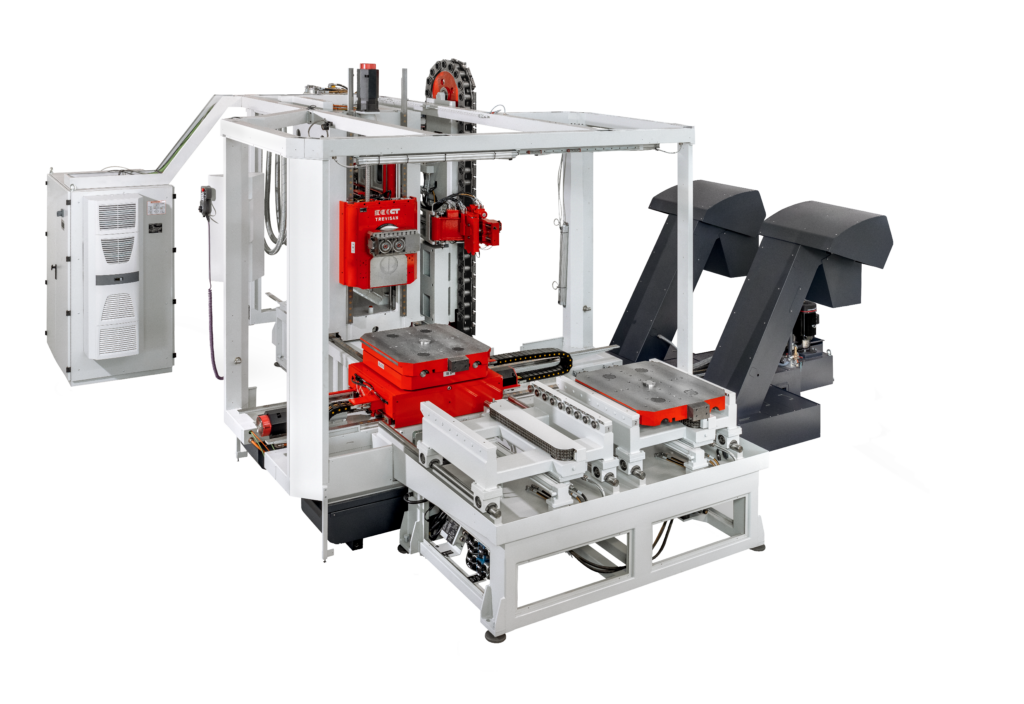

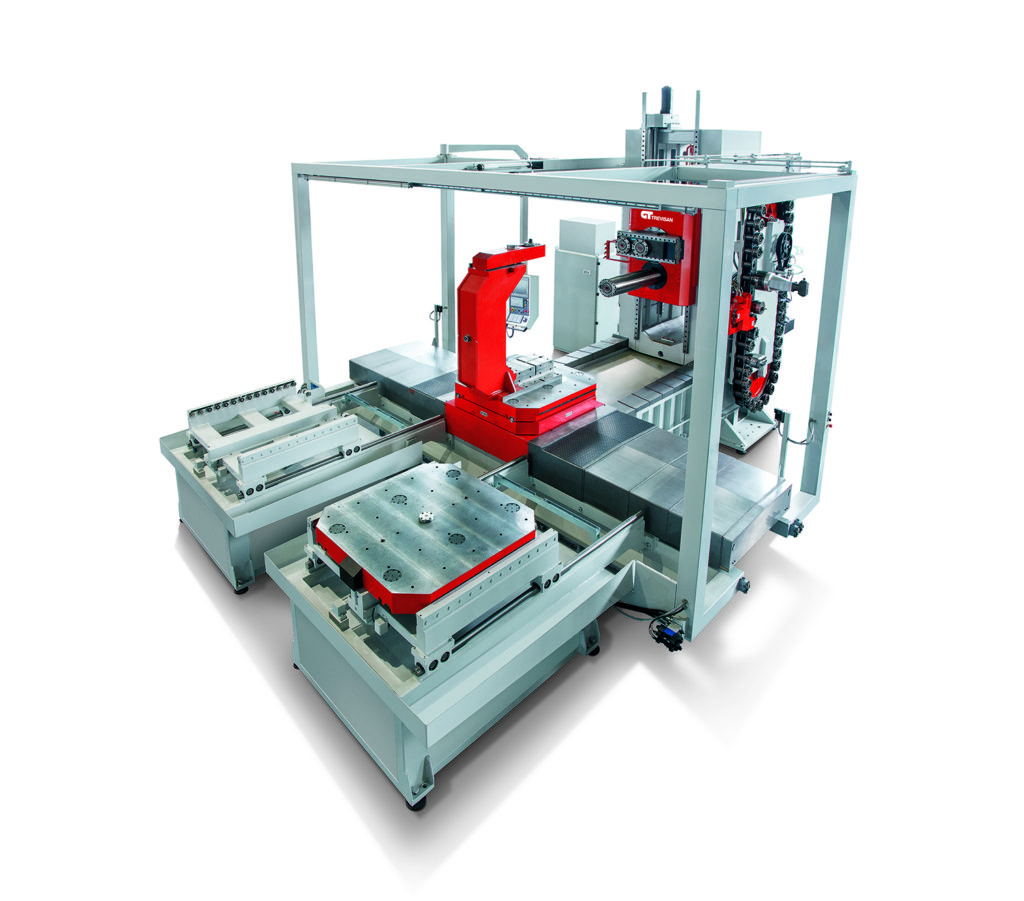

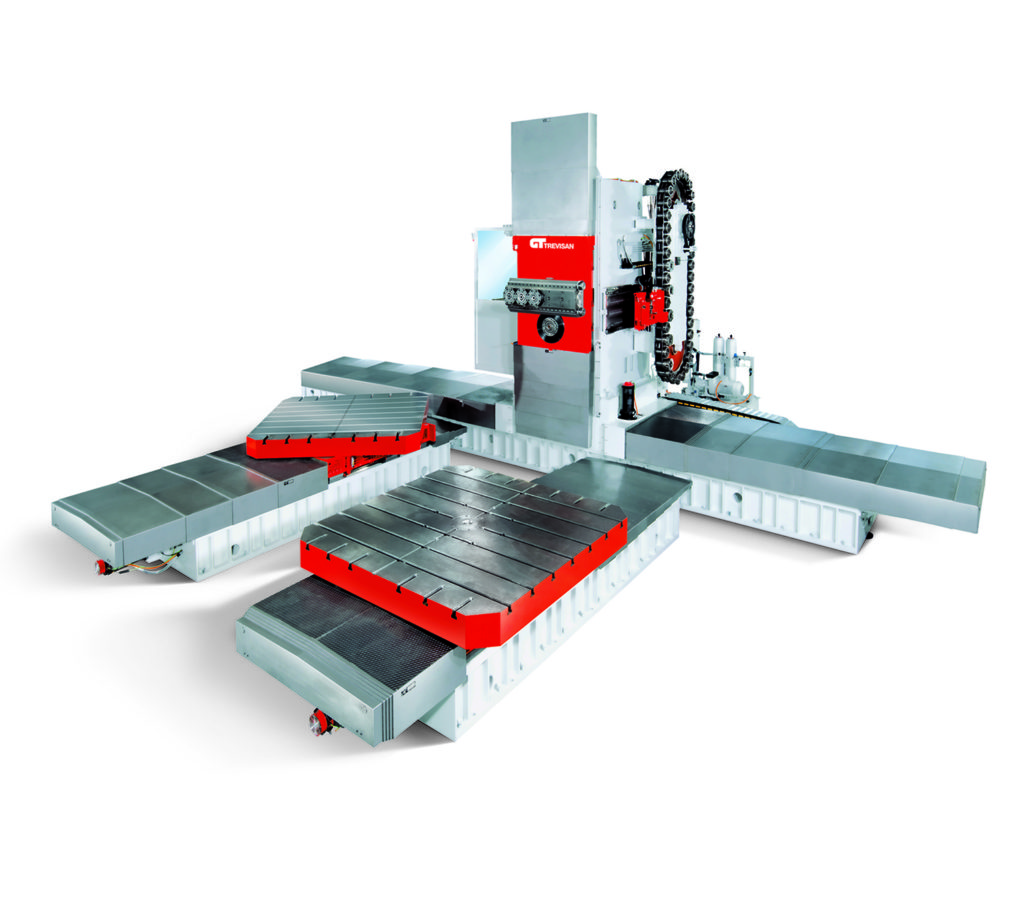

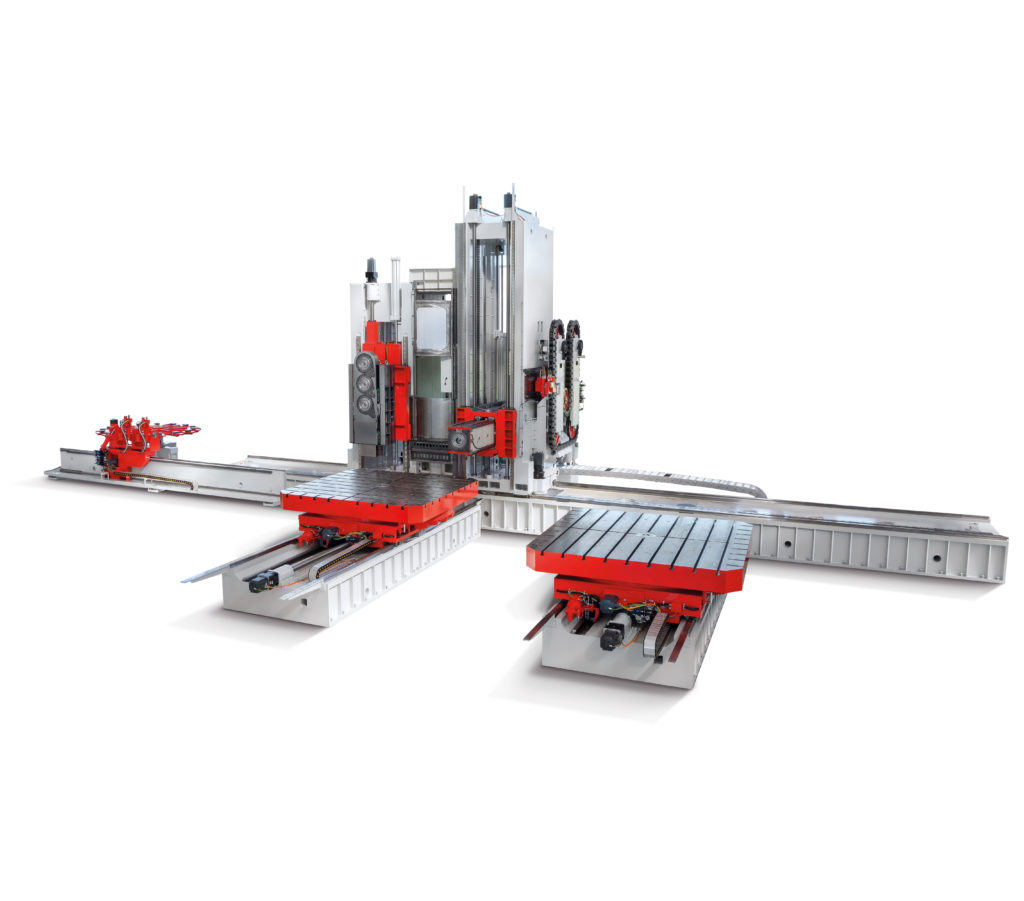

At Trevisan Machine Tool, our selection includes a range of horizontal machining centers to meet your requirements. These machines perform milling and turning in a single setup at high capacity. With integrated facing heads, two independent spindles perform jointly on a stationary workpiece as they rotate in this U-axis system.

Our machines feature varying sizes, contouring capabilities, turning diameters and other components that make them uniquely suited for various applications. Our horizontal machines are versatile and can produce multi-functional applications, including drilling, contouring, facing, boring, turning and tapping. They work at variable speeds and are compatible with numerous cutting tools. Their larger surface area allows these machines to operate colossal parts at impressive speeds.

BENEFITS OF OUR 5-AXIS CNC MACHINES

With the right machining center, you can boost efficiency and impact your bottom line by securing the highest return on investment. Partner with Trevisan Machine Tool and gain the following benefits:

- Dual-spindle design: Our machines produce higher quality parts through dual spindles that ensure precision finishing for a superior end product.

- Reliable and efficient machining centers: Experience peak efficiency for decades with our versatile, durable machining.

- Trustworthy support team: Count on our experienced support team for technical advice via after-sales support services.

- U.S.-based company: We are proud to be based in the U.S. and offer fast local shipping for machines and spare parts.

CONTACT US FOR MORE INFORMATION OR ORDER TODAY

Whatever your requirements and applications, we can help you secure a high-quality, versatile CNC machine. Contact us today to request more information or place an order. Our expert team is standing by to discuss your needs.