MACHINES USED FOR THREADING

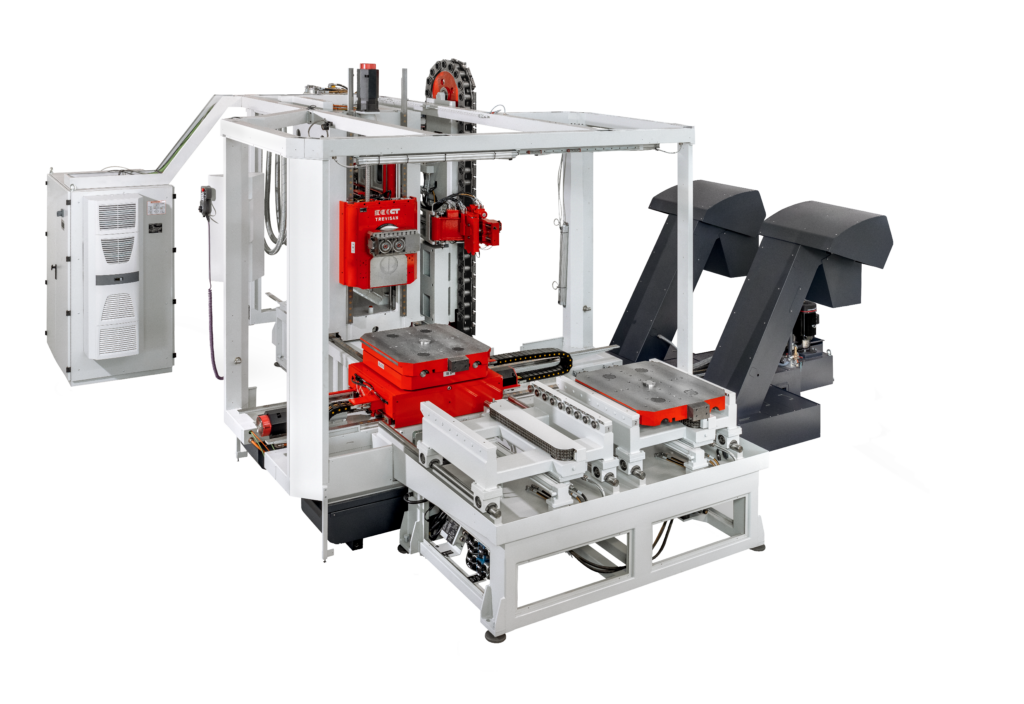

Trevisan Machine Tool offers highly developed horizontal machining centers for high-production facilities. Our CNC machines can perform various production functions in a single setup, including thread milling and single point threading, maximizing production efficiency and minimizing quality accidents.

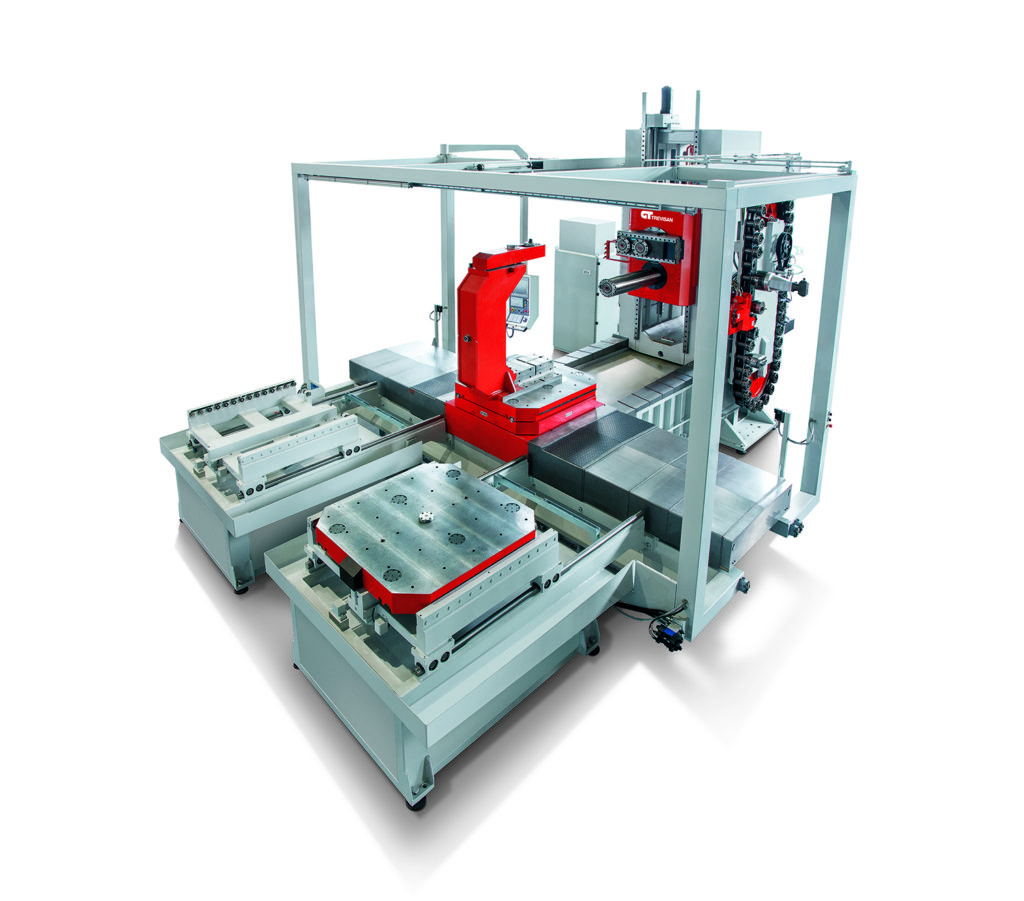

Trevisan Machine Tool’s CNC machining centers optimize production efficiency and increase quality results with an integrated facing head. This element allows the machine to move around the piece for higher accuracy when manufacturing larger pieces and specialized machinery.

CNC Single Point Threading

Single point threading is a technique for cutting threads on a workpiece. This process is normally done with a single cutting head attached to a lathe that moves linearly or horizontally to a rotating workpiece. There are many applications of single point threading across the manufacturing industry, ranging from creating the internal threads of a bolt to forming threads on a pipe.

CNC Thread Milling

The thread milling method cuts threads with a tool that has a limited contact area with the part or workpiece. This tool follows a circular path around the thread to cut a hole, rotating at a relatively high speed. This technique is used for cutting threads in materials that do not have the best machinability.

CNC Threading Machines From Trevisan Machine Tool

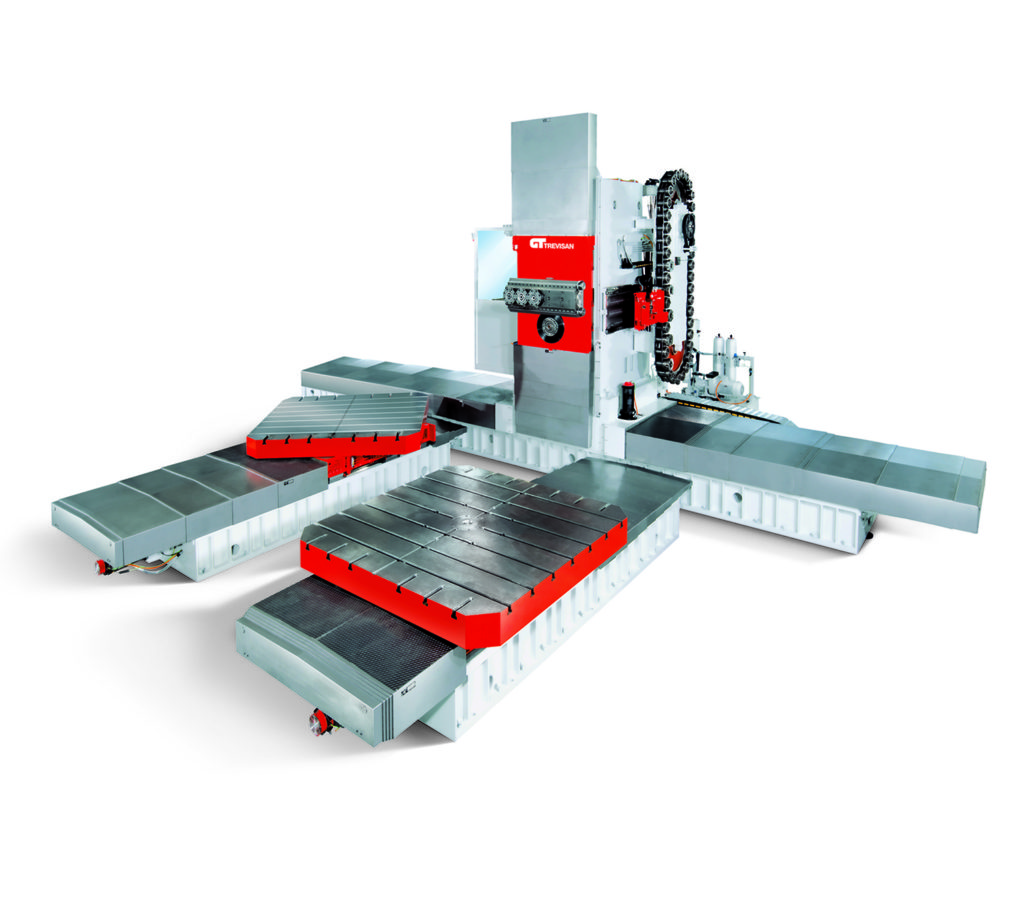

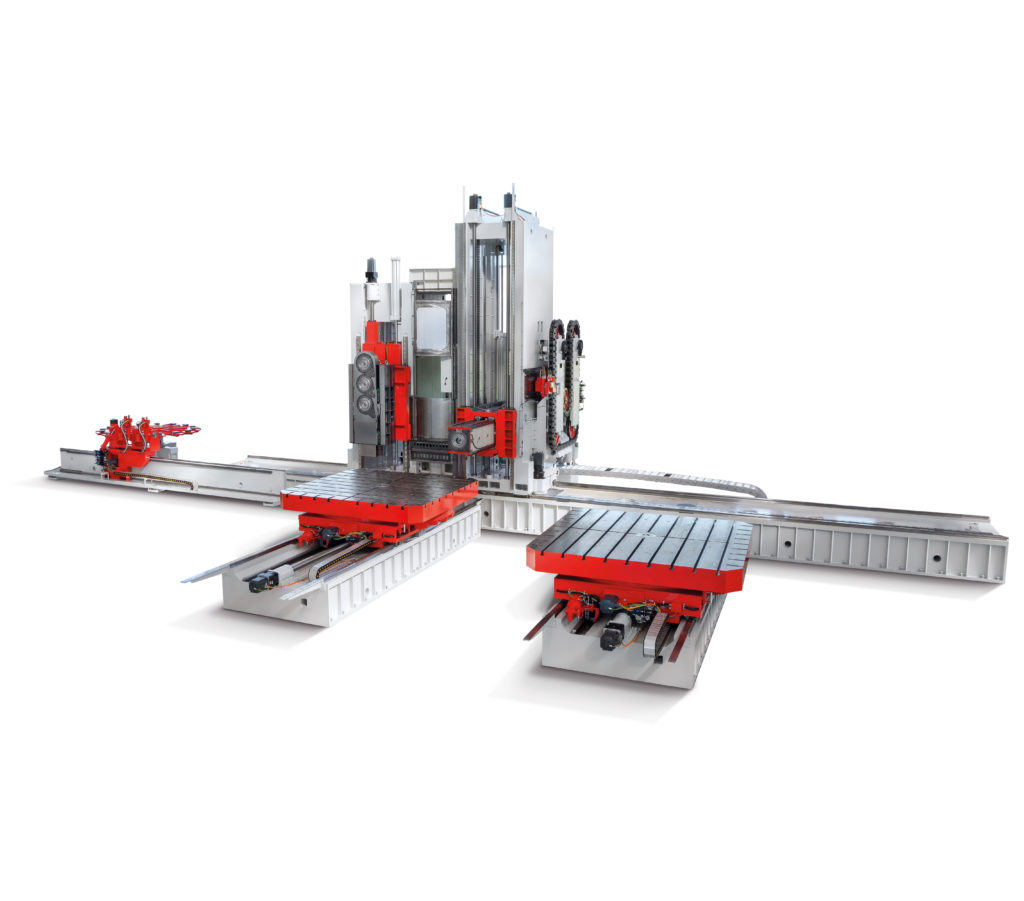

At Trevisan Machine Tool, we offer a lineup of machines that accommodate various machining applications, with unique features that distinguish us from other manufacturers. We manufacture CNC machines that hold the part stationary while the machine moves around it, which allows them to machine a broader range of products than conventional equipment.

Our horizontal machining centers are designed with two spindles, allowing them to complete the entire machining process with one setup, optimizing efficiency and accuracy. Our versatile machining centers can also be used to perform both single-point threading as on a CNC lathe, as well as thread milling like you would on a CNC mill.

The integrated contouring head rigidly and accurately cuts all turning features, providing high-quality results without switching operations. These features are perfect for pipe threading, allowing you to work faster on large workpieces from start to finish with a CNC pipe threading lathe.

If you’d like to see these prime features in action, watch our YouTube video to see our DS300 horizontal machining centers turning and threading a pipe.

Benefits of Choosing Trevisan Machine Tool for Your CNC Threading Needs

Trevisan Machine Tool is a U.S.-based company that has been producing machining centers since 1963. We offer high-quality and exceptional customer support to solve the most challenging manufacturing projects. From our integrated U-axis contour machining centers to our customized multitasking turning centers, we keep your operation running at maximum capacity.

Partnering with Trevisan Machine Tool for threading can benefit you in a few key ways:

- Reduced costs: Various production requirements on a part can be performed with minimal equipment, in shorter times, and with less human intervention, resulting in universal cost savings.

- Higher quality: Consistent, accurate results through calibration and turnkey options from their customized programs, minimizing the possibility of part defects.

- Streamlined operations: Maximize production efficiency — their versatility prevents bottlenecks and takes steps from production.

Experience the Trevisan Difference Today

Trevisan Machine Tool delivers solutions that meet the most demanding production and quality requirements for single point threading or thread milling. Our varied lineup of horizontal machining centers can reach up to 3 meters in diameter and be programmed to enhance your production process and produce higher-quality components.

Contact our team online for a free quote, or call us to learn more about our machining solutions from our experts.