CNC Machining for the Energy, Oil and Gas, Nuclear and Renewable Industry

CNC machining technology has become a necessity for most manufacturing industries, as it can produce complex parts consistently and within tight tolerances. The renewable and nonrenewable energy industries rely on CNC machining to make thousands of components. Here at Trevisan Machine Tool, we offer a broad selection of CNC systems, providing everything from frac machining centers to wind turbine hub machining capabilities.

Energy Industry Machining Solutions

The energy and oil and gas industries have stringent requirements since they often deal with hazardous materials. For instance, nuclear power plants have to contain and transport radioactive materials safely, so their equipment must be made with durable components and produced according to strict standards. As a result, quality and repeatability are paramount for manufacturers in this industry.

Trevisan Machine Tool specializes in CNC machines for the oil and gas industry and other power sectors. Our CNC equipment excels at producing the specialized components common to this field, including heavy-duty elements that must withstand harsh environments. Our available types of CNC machine centers include:

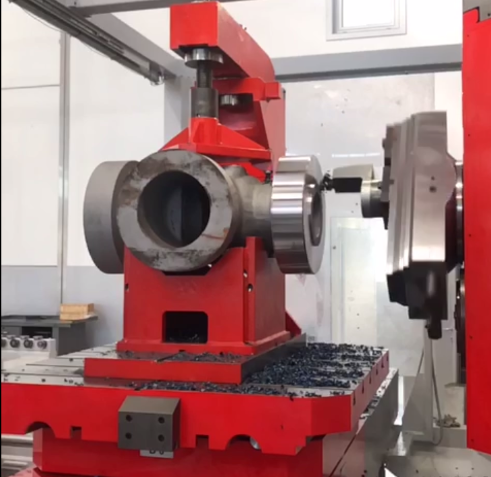

- Horizontal CNC machining centers: Our horizontal machining centers have a dual-spindle design that allows them to perform milling and turning operations without requiring multiple setups. Whether machining valves, frac blocks or slurry pumps, these machines have spacious tables suitable for objects of various sizes.

- Vertical CNC machining centers: Our multitasking vertical machining centers can handle drilling, tapping, transferring and stamping. Their ability to execute multiple operations helps manufacturers increase their productivity without adversely affecting precision.

- Modulo Equipe: Our Modulo Equipe units are multi-turret flexible machines that equip manufacturers to produce parts faster and more efficiently. We can customize each spindle to perform multiple operations simultaneously or in a step-by-step process.

How CNC Machining Centers Address Challenges in the Energy Sector

Trevisan Machine Tool offers advantages to many industries, but specifically the energy sector. With tight tolerances and concentricity being major requirements for machining in this industry, our dual spindle design allows you to do all of this machining in the same setup. Our machining solutions allow us to address common challenges in machining parts for the energy sector. These innovative solutions include:

Wind turbines are very large and typically require multiple setups on multiple machines to perform turning and milling operations. A Trevisan DS1200 can do all of the work in one to two setups while maintaining concentricity throughout the part. Trevisan Machine Tool can provide durable CNC machining centers for wind turbine nacelles and other essential components.

Valves are a critical component in the energy sector and are held to very strict quality standards. Over 60 years ago, Trevisan started building machines specifically for machining gas valves. The b-axis table combined with our dual spindle design allows you to machine most valves in a single setup while maintaining critical concentricity and tight tolerance seats. Our horizontal machining centers are perfect for valves up to 10 feet in diameter.

The gas and oil industry requires subsea machining centers with rugged construction and the ability to function below rough seas. Oil rigs also need heavy-duty machining centers to manufacture pipe components needed for leak-free oil transport.

Fluid ends, also called Frac Blocks, are vital pieces of the fracking process. Each block endures extremely high pressure and must be highly precise to be safe and efficient. Fluid ends are one of the most commonly machined parts on a Trevisan DS600/200C series. Our integrated facing head allows you to turn each port on the block and maintain .001-inch tolerances with ease. Our DS600 RAM can machine these blocks from raw stock to a finished product.

Flanges are an important piece in many manufacturing industries, including the energy sector. Flanges help to seal a pipe or pressure vessel safely to another pipe and are typically used in large quantities, which is why the Trevisan Pick Up is designed to produce flanges at a high rate. A Trevisan Pick Up is an automated vertical turning line that will take your raw forging to a complete and engraved part in seconds.

Contact Us (sidebar)

"*" indicates required fields

Contact Us for More Information on CNC Machining Solutions

Here at Trevisan Machine Tool, we offer versatile energy CNC machining centers suitable for demanding applications, including those common to the renewable and nonrenewable energy industries. For more information on our CNC machining solutions, fill out an online form to get in touch with one of our professionals.