4-AXIS MACHINING

A 4-axis milling machine, with an additional axis for increased cutting precision and smoother operation, is the solution to numerous industry applications. These versatile machining centers are suitable for milling, drilling, boring, turning and other complex operations. Having the right 4-axis machining center is imperative to ensure a seamless workflow.

4-AXIS MACHINING COMMON APPLICATIONS

Four-axis CNC mill machines from Trevisan Machine Tool are commonly used across several industries, including:

- Automotive: Designing and manufacturing car parts like gearboxes and engine blocks.

- Aerospace and defense: Used to produce aircraft and other aerodynamic components.

- Energy: This includes oil, gas, nuclear and renewable energy source components.

- Industrial: Common industrial machining applications involve heavy-duty equipment, industrial pumps, gear and bearing housings, gearboxes and impellers.

ABOUT OUR MACHINING CENTERS

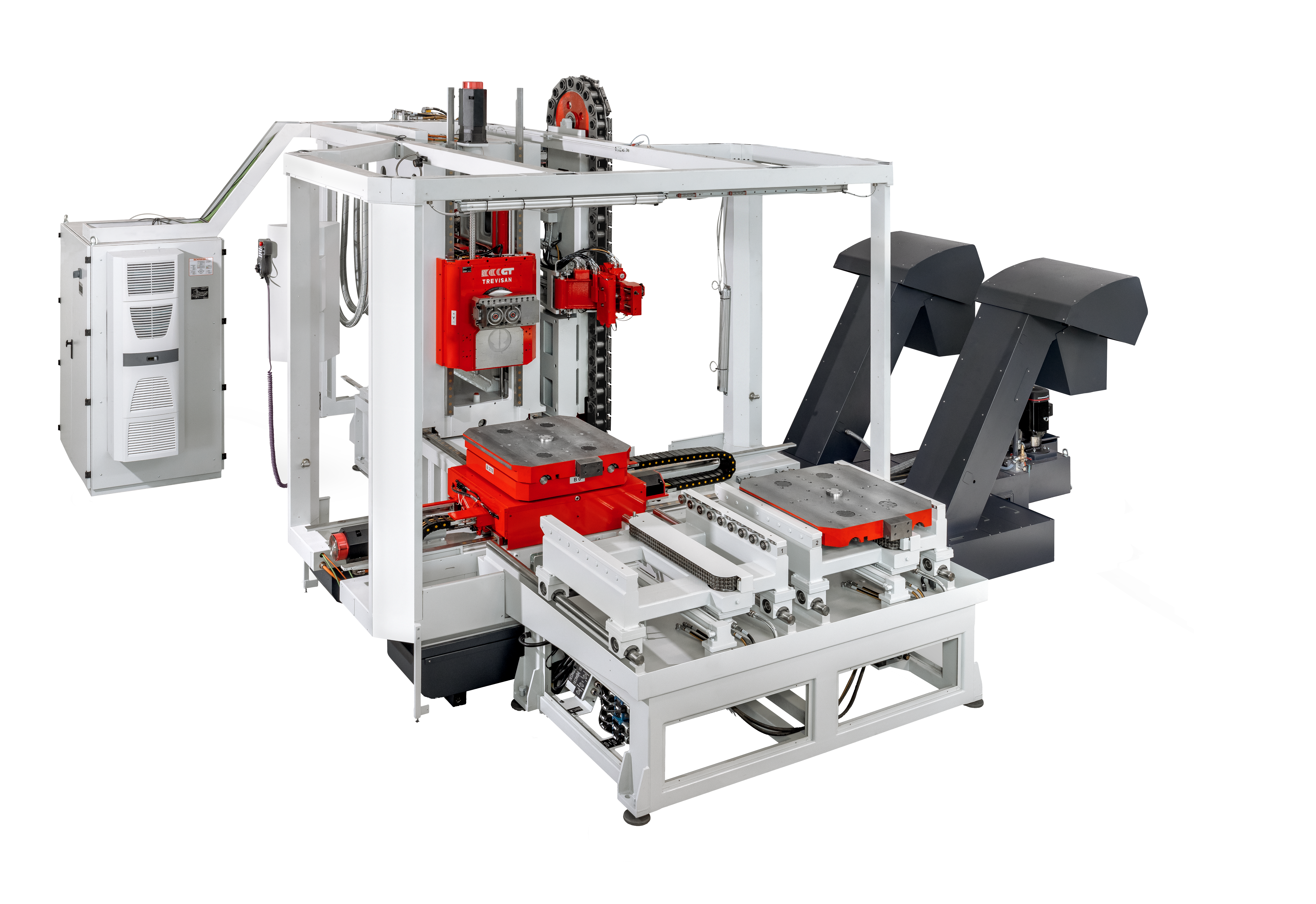

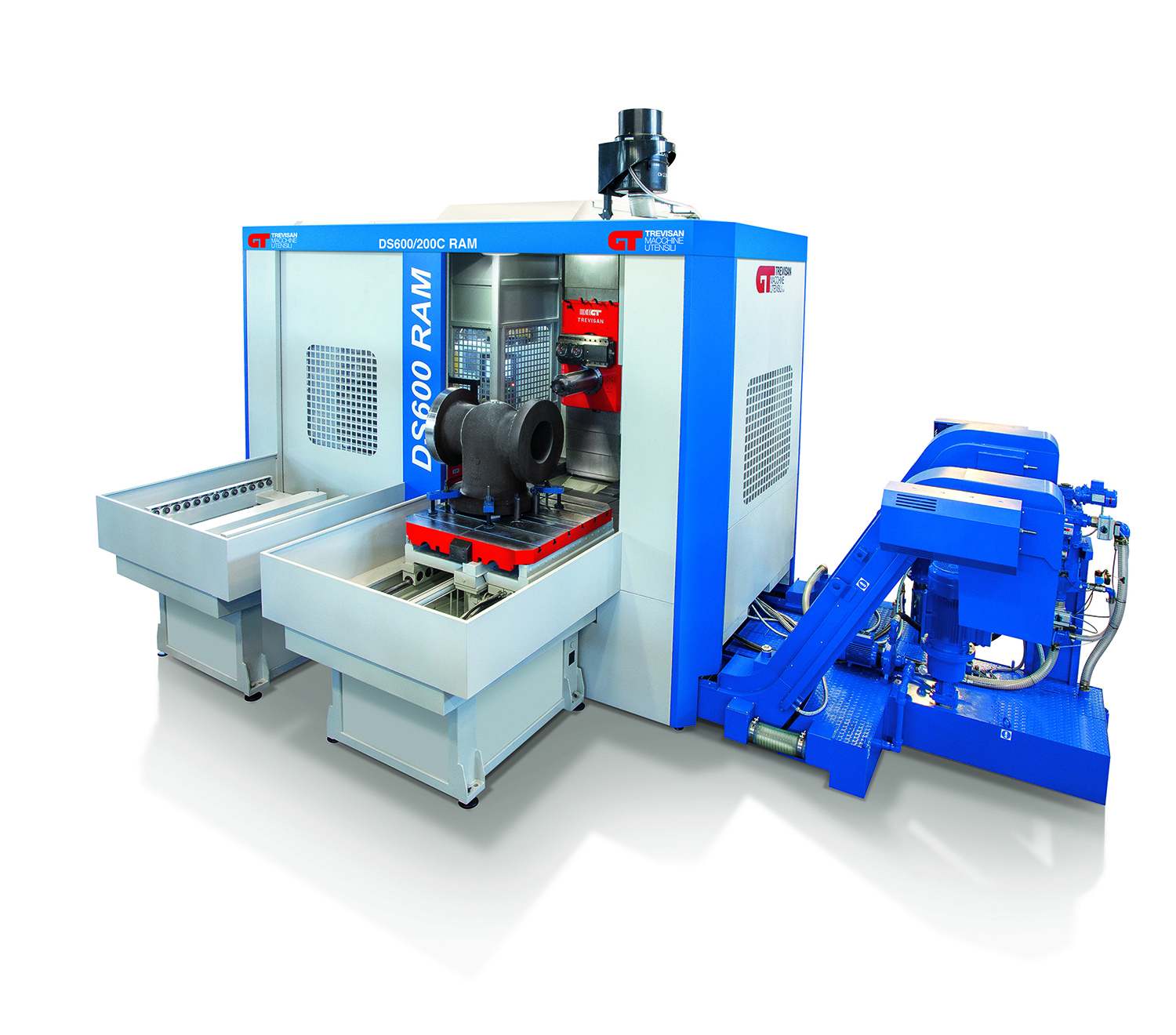

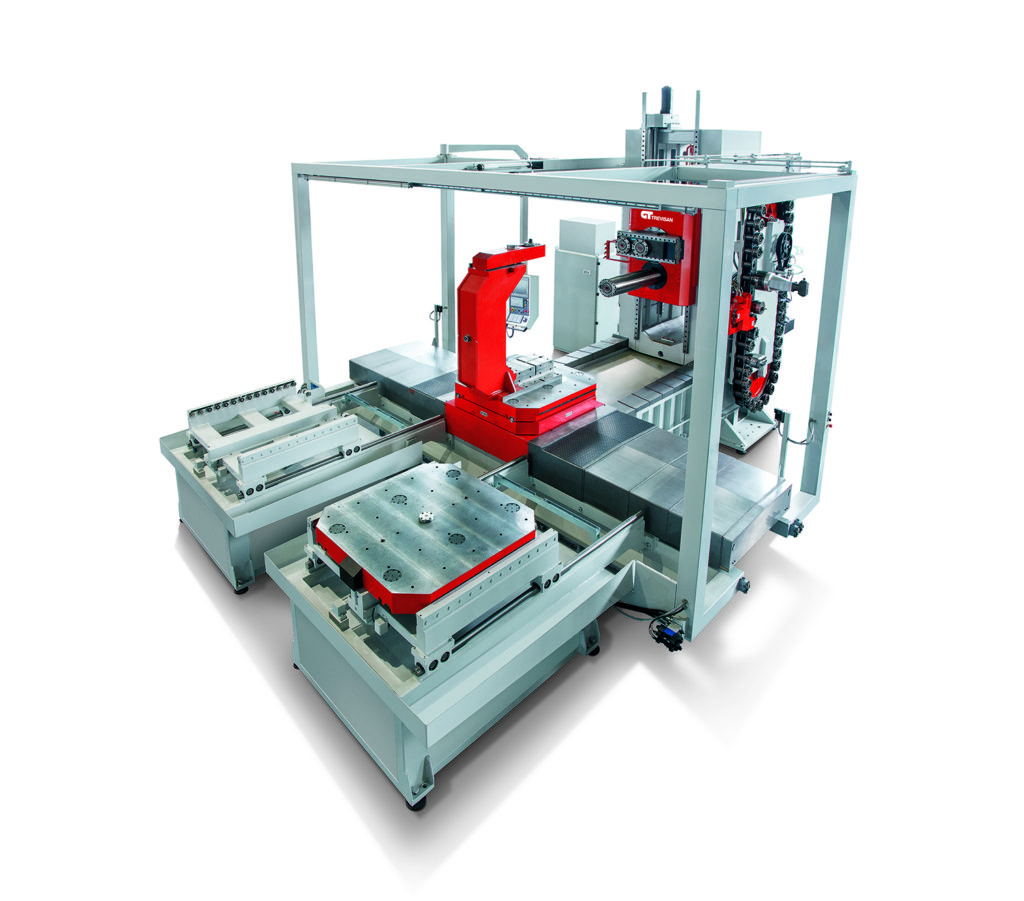

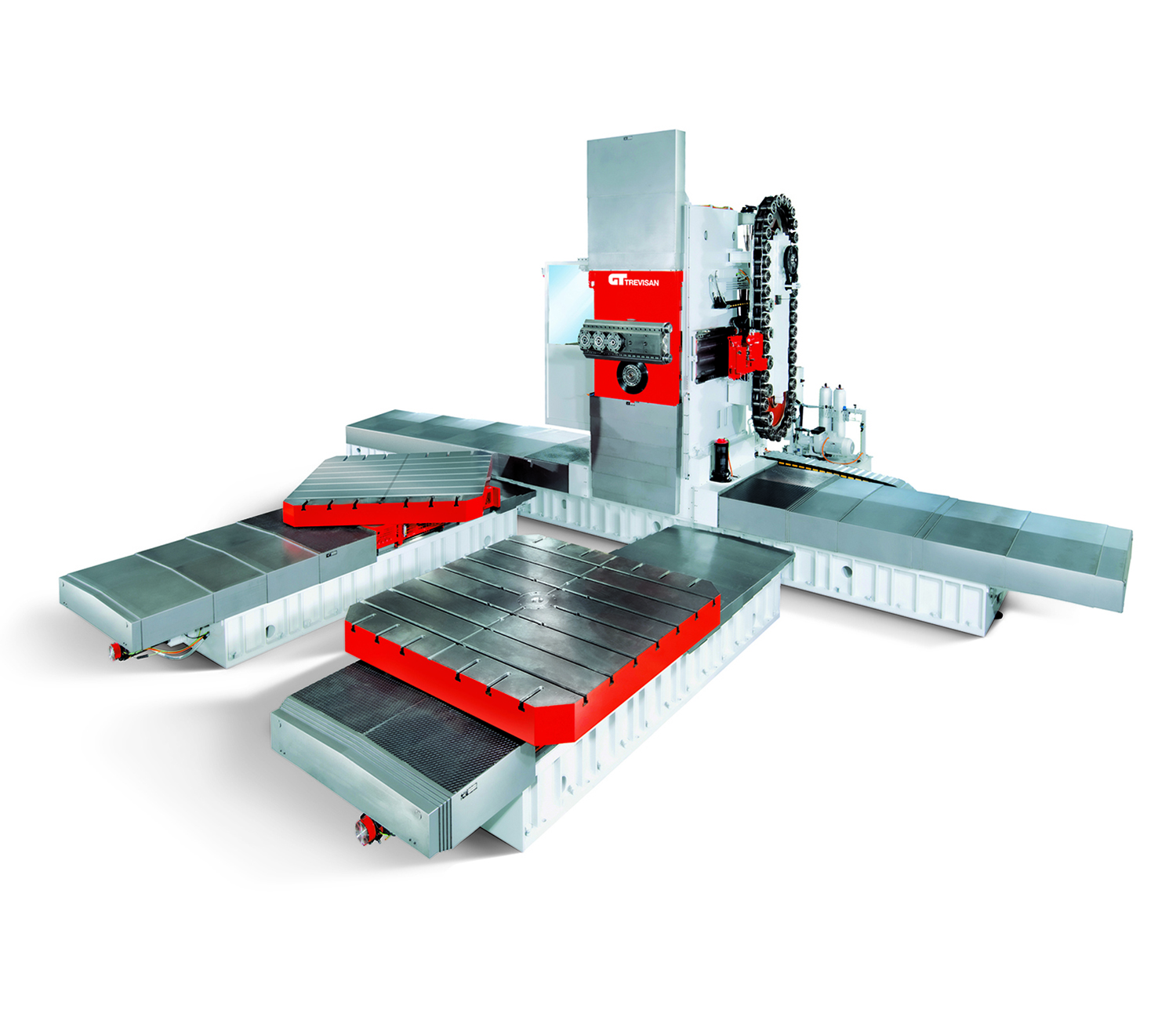

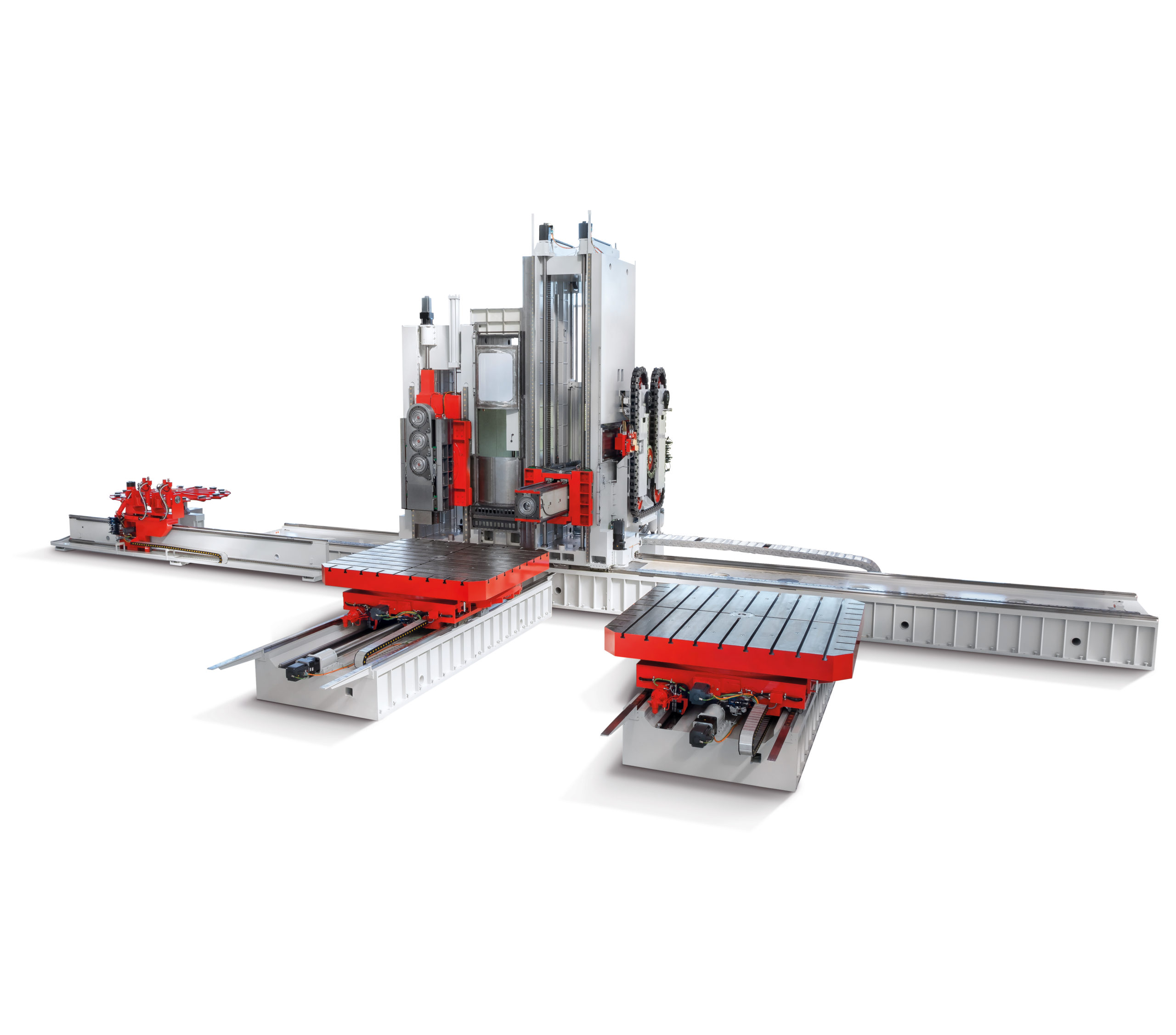

With horizontal 4-axis CNC machines, horizontal dual spindles create intricate, deep cuts with high-quality finishes. Workpieces remain fixed while the spindle cuts away at varying speeds, providing optimal turning efficiency. The dual spindle design allows for milling and turning in the same setup, while the integrated facing head ensures accurate stationary turning. The dual-spindle feature sets Trevisan Machine Tool apart from other options available.

With heavy-duty machining centers, you can effortlessly complete single-setup tasks. We carry models in various sizes, power capabilities and configurations to best suit your needs. Choose a smaller, heavy-duty machine that can perform at a higher speed or opt for our milling monster, the DS1800/560C, for the ultimate power solution and the largest integrated facing head in the world.

Our team has the knowledge and expertise to provide the best advice and service for our comprehensive machining centers.

HIGH-QUALITY MACHINING

Our options include features that set them apart from competitors, including U-axis horizontal machines with varying integrated facing head sizes and turning diameters for precision milling, turning and more.

The U-axis machine improves performance and has other benefits, such as reducing machine changeover, improving production efficiency and enhancing part quality.

Another key feature of our horizontal machining centers is they can be built from 4-axis to 6-axis based on your application requirements.

BENEFITS OF OUR 4-AXIS CNC MACHINES

Whether you need a standard horizontal machining center or a special custom build, each model we offer has its benefits. At Trevisan Machine Tool, we pride ourselves on maintaining high-quality equipment for numerous industry applications. Explore the benefits of choosing us for your machining needs:

- Efficient after-sales support: Our support team is always available for maintenance and repairs so your machines run optimally.

- Training programs: Trevisan Machine Tool provides training and on-call support for programming or technical issues and questions, equipping users with first-hand knowledge for a prompt resolution.

- U.S.-based company: We are proudly local and based in the U.S., offering support and an extensive spare part inventory.

At Trevisan Machine Tool, we understand that time is money. We want to save you both. Our experts are ready to learn about your industry-specific CNC machining center requirements so we can tailor our solutions accordingly.

To place an order or learn more about our selection, speak to an expert today.