Machines Used for Drilling

CNC drilling involves using special cutting tools to create precision holes in a workpiece. This machining process’s primary objectives can range from enhancing aesthetics to producing holes for bolts and screws. Advanced CNC machining centers with high-speed drilling capabilities can seamlessly integrate drilling operations with many other tasks, offering a level of accuracy and precision that is difficult to match.

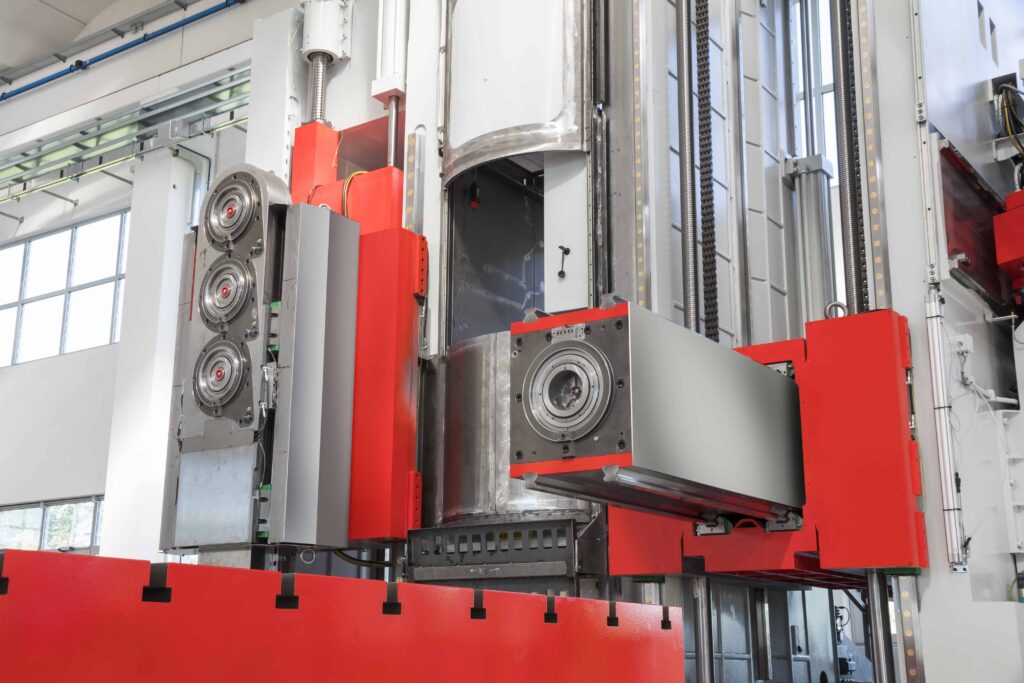

Trevisan Machine tool offers state-of-the-art horizontal machining centers that can perform multiple production functions in a single setup, from drilling and tapping to milling, contouring, turning and facing. We’re different from similar drilling and milling machine manufacturers because we offer multi-spindle centers with various turning head diameters and multiple-facing head sizes. Our diversity and versatility enable you to choose the most practical and efficient solution for your unique production needs.

CNC Drilling and Tapping Machining Centers

Horizontal milling centers from Trevisan Machine Tool provide stability and rigidity during drilling, ensuring the drilling tool remains perpendicular to the workpiece, resulting in straight and accurate holes. Our machining centers feature automatic tool changers and multiple-axis movements that enable them to handle various drilling and other machining requirements quickly and effectively. They can accommodate numerous drill sizes and depths, making them versatile machines for valve drilling and other machining applications.

Our solutions range from compact models with milling spindles capable of reaching 4,500 RPM to heavier-duty solutions with added power and increased turning capacities. Whether you’re aiming to save floor space, increase production speeds or minimize changeover times, we can help you find a solution that solves your production challenges.

Benefits of Choosing Trevisan for Milling, Drilling, Tapping and Other Machining Centers

Selecting Trevisan’s machining centers adds a new dimension to your production capabilities, delivering all the benefits of a traditional lathe machine without the disadvantages. Having the ability to drill, turn, mill, contour, bore and perform other functions on the same machine allows you to experience benefits like:

- Minimal equipment: With a versatile machine, operations can perform various production requirements on a workpiece without transferring it to different equipment, saving time, reducing setup costs and increasing overall efficiency. This benefit also results in cost savings for equipment maintenance and upkeep.

- Increased accuracy and precision: By performing multiple tasks in the same setup, there is less chance for misalignment or inconsistency between different machines, resulting in higher-quality finished parts.

- Improved workflow: With one solution capable of performing multiple functions, operations can streamline production lines and reduce the time and effort spent on extra setups and material handling.

- Enhanced versatility: Businesses can easily switch between numerous machine processes based on their needs, allowing greater production versatility and responsiveness to customer requirements. Increased versatility can also lead to new opportunities.

Learn More About the Trevisan Difference Today

Trevisan Machine Tool has helped customers find practical and effective machining solutions for their specific production requirements since 1963. We offer a comprehensive range of milling centers, including equipment that can perform multiple tasks like drilling, boring and tapping with one setup. Contact us online today for a quote or to request additional machine specifications.