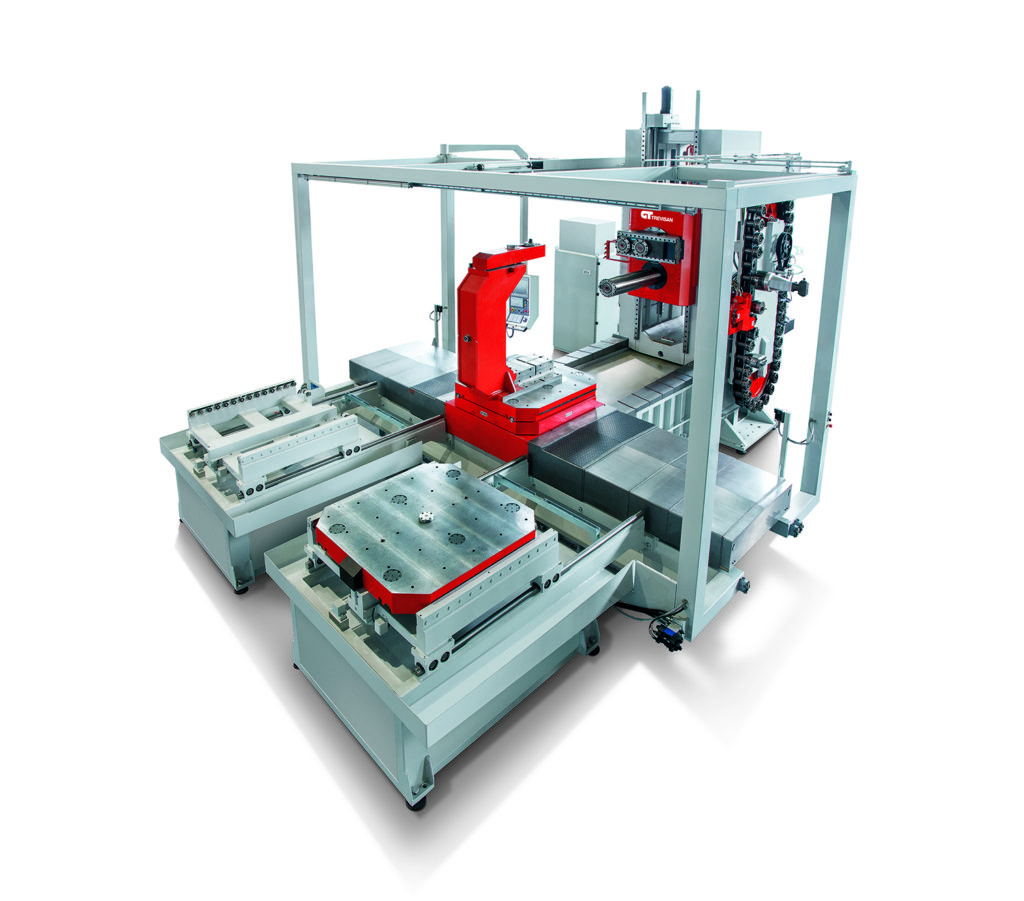

HORIZONTAL MACHINING CENTERS

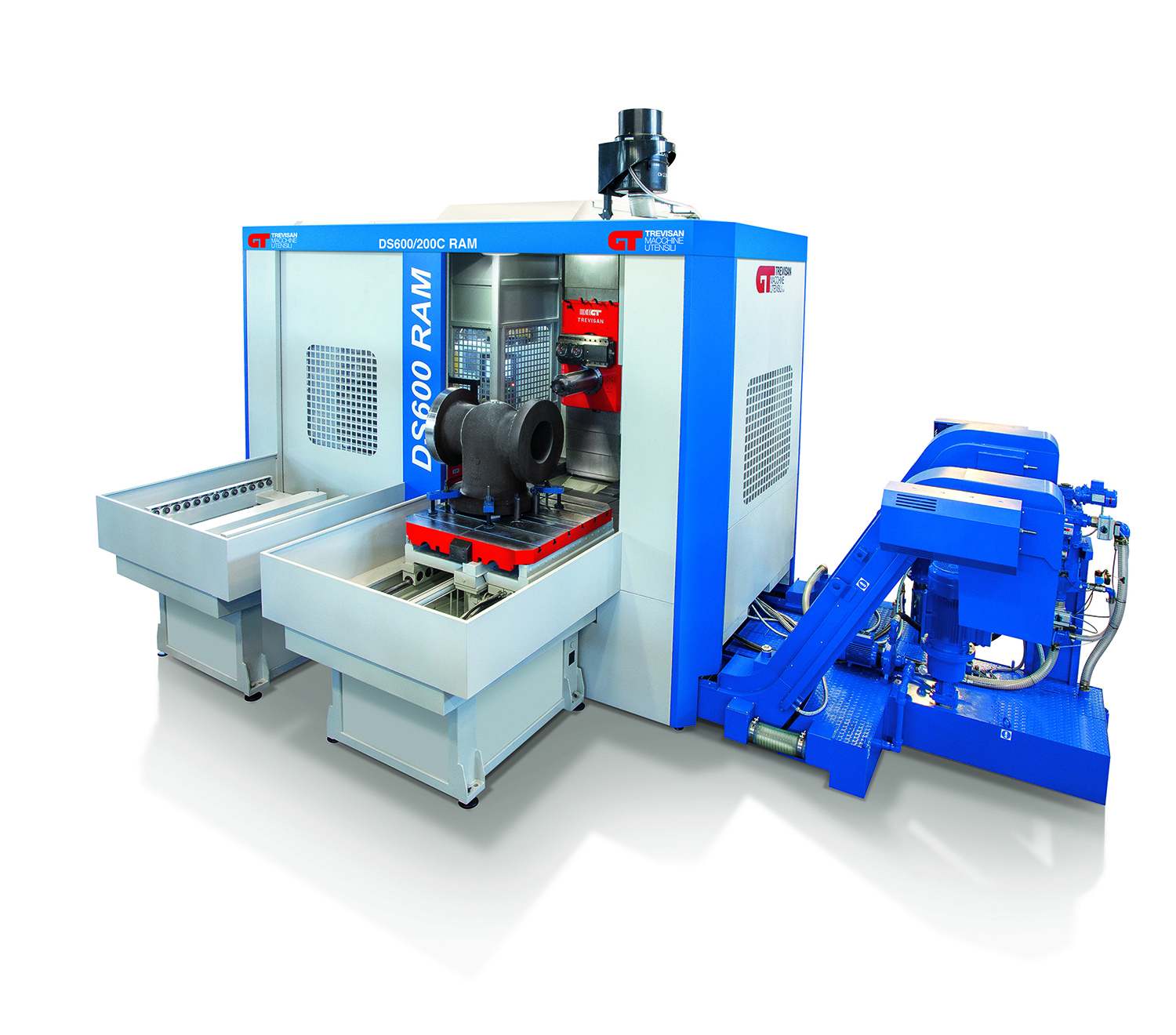

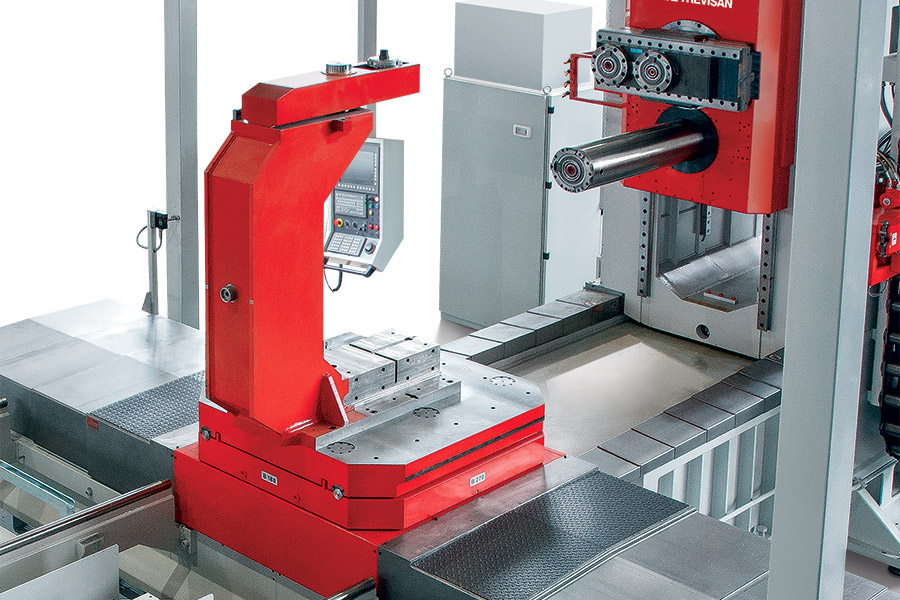

Trevisan Machine Tool offers one of the industry’s most comprehensive selections of horizontal milling machines with integrated facing heads. Our equipment line can accommodate machining applications with turning capacities of up to 3,000 millimeters.

Machines

Horizontal Cnc Milling Machines With Integrated Facing Heads

Our best CNC machines for metal work include:

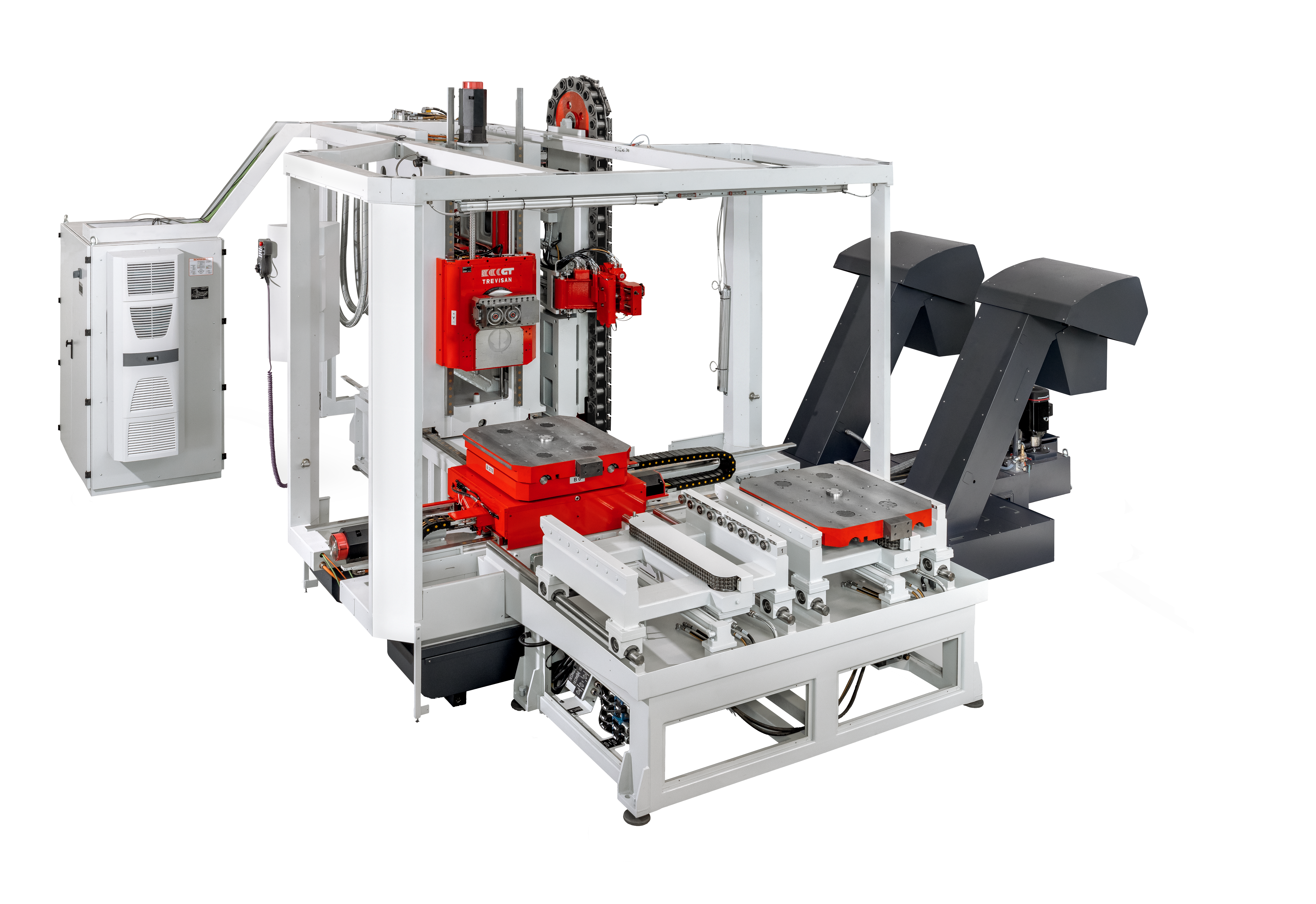

GT350

Centers

TREVISAN’S HORIZONTAL MACHINING CENTERS

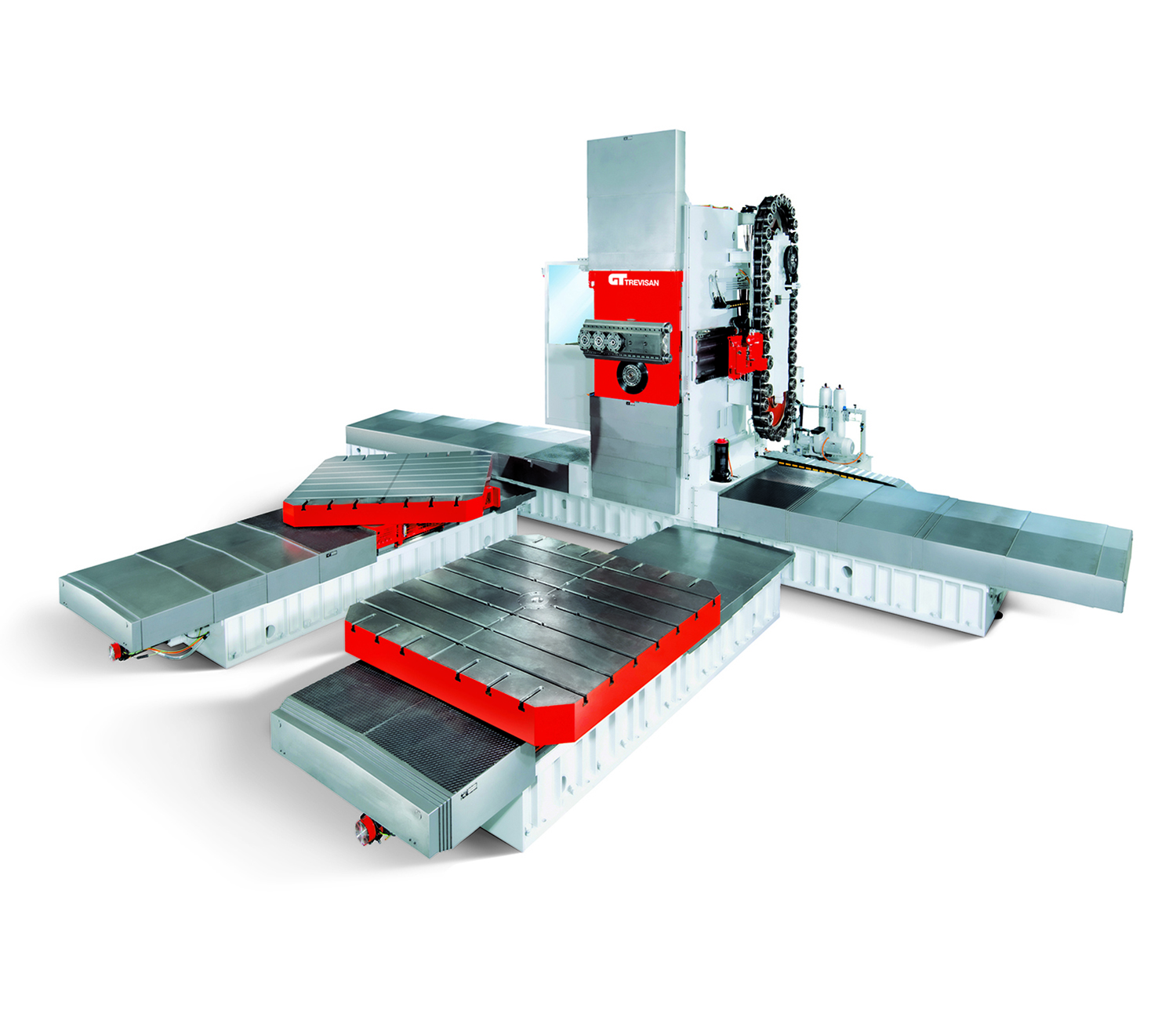

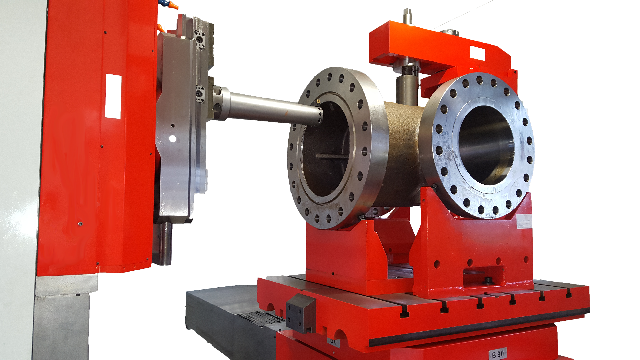

Horizontal milling machines set the standard for speed, accuracy and precision in large production runs. These machines feature spindles in a horizontal position, allowing for deeper and heavier cuts on a workpiece. Horizontal U-axis machines work well for oversized components because they have larger tables, allowing you to perform turning operations without needing to balance parts in a lathe’s chuck.

The horizontal setup allows chips to fall away safely and efficiently, helping to achieve a smooth, high-quality finish. The horizontal machining concept surrounds keeping a workpiece stationary while the machine’s tools perform complex computer numerical control (CNC) operations without changing fixtures. More importantly, horizontal mills offer variable speeds and the ability to work with an extensive cutting tool range.

At Trevisan Machine Tool, we offer a lineup of horizontal CNC machines for metal cutting to accommodate a comprehensive range of machining applications.

applications

Cnc Horizontal Machining Center Uses And Applications

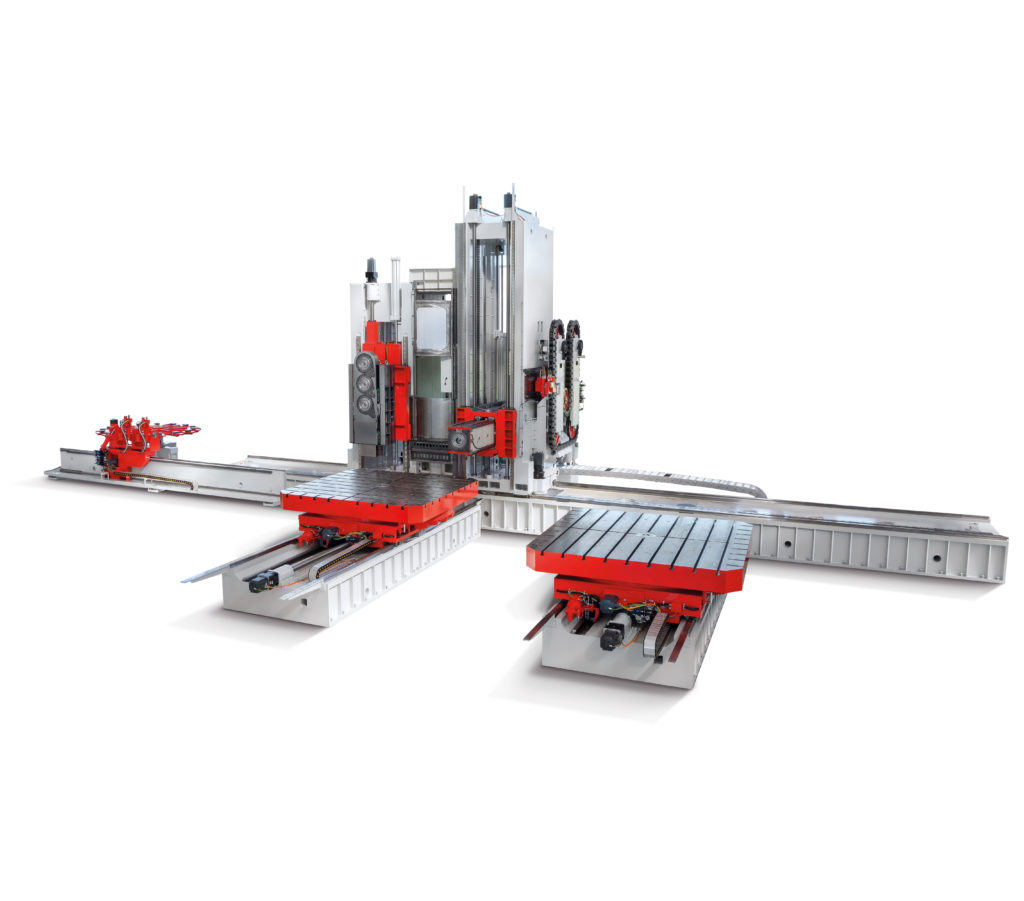

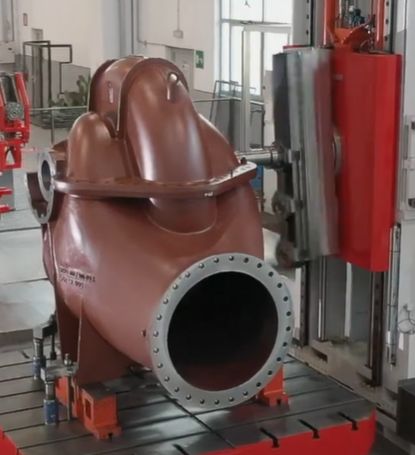

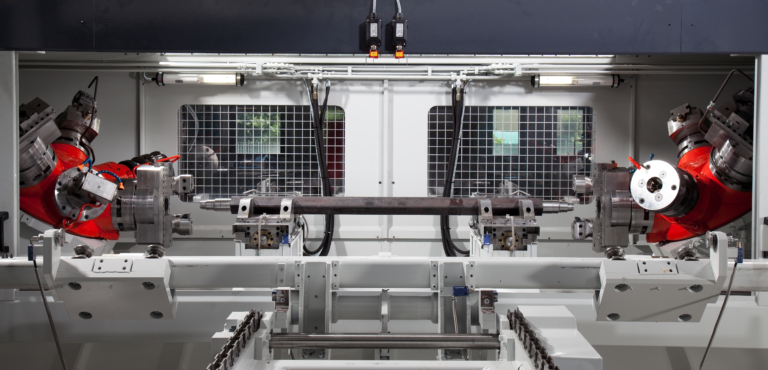

The dual-spindle design allows our horizontal milling machines to perform turning and milling operations in a single setup. Because of the horizontal configuration and multiple spindles, our equipment can machine more parts with higher-quality surfaces than most conventional production equipment. One of the most significant benefits of these machines is that they can turn components without rotating the actual workpiece, enabling faster production times while creating a much safer work environment.

Our Horizontal CNC Machining Centers can perform various production functions on the same machine, including:

Our advanced CNC machining centers utilize sophisticated programming to create complex geometric shapes and profiles during contouring operations. The horizontal configuration enables excellent chip evacuation during contour cutting while producing exceptional surface finishes. This capability is particularly valuable for aerospace components, medical device housings and precision automotive parts where complex geometries are essential.

Our machines keep the workpiece stationary while the cutting tool rotates around it. This functionality enhances safety, improves accuracy and can produce significantly larger parts than traditional lathes. The setup is ideal for valve bodies, industrial rollers and heavy equipment components with high concentricity.

The dual-spindle design delivers superior boring capabilities with high precision and repeatability. The horizontal configuration ensures consistent hole quality and chip evacuation during deep-boring operations. These capabilities are perfect for the precision boring of engine blocks, pump housings and larger industrial components requiring tight tolerances.

Robust spindles and rigid construction enable our machining centers to deliver powerful milling performance. They offer heavy cutting capabilities in tough materials while maintaining precise tolerances. The horizontal orientation allows better tool access and chip evacuation, resulting in superior surface finishes. These features make our machines ideal for milling complex aerospace components, dies and molds

Our integrated facing heads provide exceptional surface finish quality and flatness in facing operations. Our machines can handle large-diameter facing with remarkable stability, ensuring consistent results across the entire surface. This capability is especially valuable for flange manufacturing, valve body production and other applications requiring precise flat surfaces.

Our milling machines improve back-facing by achieving perfect alignment with front-faced surfaces. This capability reduces production times and improves efficiency by eliminating the need for multiple setups. The improved part quality and precise positioning benefit parts production for industries like oil and gas, heavy equipment, and power generation.

Our machines’ rugged construction and precise control systems boost tapping efficiency and accuracy. Our equipment can perform tapping in multiple orientations with exceptional thread quality. The integrated facing head also allows you to perform single point threading, great for larger precise threads. This versatility is particularly valuable in industries requiring high-precision threaded components, such as aerospace, defense and industrial equipment manufacturing.

CNC drilling involves using special cutting tools to create precision holes in a workpiece. This machining process’s primary objectives can range from enhancing aesthetics to producing holes for bolts and screws. Advanced CNC machining centers with high-speed drilling capabilities can seamlessly integrate drilling operations with many other tasks, offering a level of accuracy and precision that is difficult to match.

If you want to learn more about how our horizontal milling machines can benefit your operation, the experts at Trevisan Machine Tool can assist you. Since 1963, we have prided ourselves on building high-quality equipment to solve the most complex fabrication challenges. Contact us online today for additional information or to request a machine quote.