SPECIALIZED MACHINING

Girolamo Trevisan founded Trevisan Machine Tool in 1963 by building special-purpose machines for unique production requirements. The company builds upon this history today, engineering custom machines to meet each customer’s ever-changing and more demanding needs. We configure many of these machines to offer a custom solution that leverages poroven technology, standard machining lines, and modified options for customers worldwide.

Specialized Machine Tools

The Trevisan Engineering team has a passion for innovation and technology. We team up to help each customer get the most out of their machines by working with them each step of the way. The process could be as simple as verifying the sizes, minor details and options needed to build the machine around your specialized product.

Modulo Equipe for Multiple Operations

Our Modulo Equipe custom machine centers are modular units configurable to perform multiple operations in one cycle. With up to six turrets on each unit, these centers can combine to create a special-purpose machine to enhance the productivity and functionality of your operation. Modulo Equipe optimizes the machining process by integrating various functions into a single machine center, including milling, contouring, turning, drilling, boring and other tasks.

By combining multiple machining operations in a single device, Modulo Equipe eliminates the need to transfer workpieces between different pieces of equipment, minimizing setups, reducing production time and increasing efficiency. More importantly, it also offers flexibility in terms of customization and adaptability to specific manufacturing requirements.

Personalized Machine Tool Examples

Trevisan has customized solutions around the world for many applications across various industries. We love to build and innovate special machines for our customers to produce parts like valves, pump housings, fluid ends and axle housings. If you send us your project needs, we can begin designing a machine around your product.

Browse several examples of the innovative solutions we have built previously.

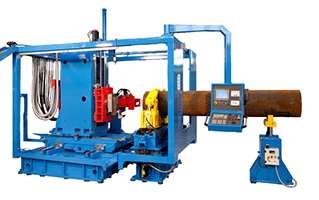

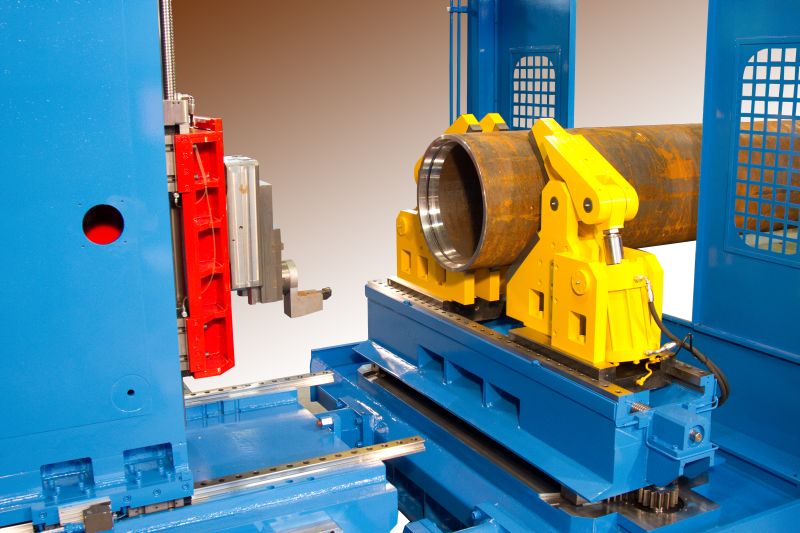

Large Pipe End Machine

We modified our DS450 machine to accommodate pipes with larger lengths and diameters by swapping the table and pallet changing system with hydraulic clamps that keep the workpiece properly centered. This configuration simplifies the spindle head as it only needs to house the U-axis contouring head.

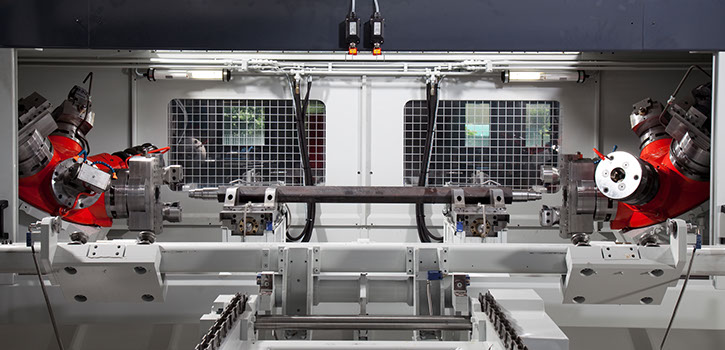

Axle End Finish Machine

Using our Modulo Equipe units with centering chucks and auto transfer equipment at each station, we designed a multi-process trailer truck axial machine specifically for roughing and finishing the ends of a large vehicle axle.

DS200 + 2 ME1 Specialized Machining Center

This machine was designed for high production of multiple parts including valve bodies, pump housings, and more. This machine has one DS200 milling spindle, 2 modulo equipe turret spindles, 3 work stations, and a load/unload station.

Double Column Machine

This Double Column Machine was designed to machine excavator components. It is equipped with two mirrored RAM spindles with a 1-meter x 5-meter-long table in between which permits you to machine both sides of the part simultaneously. Each spindle also has universal heads which allow you to mill, drill, tap, etc. at virtually any angle.

Connect With the Experts at Trevisan Machine Tool Today to Learn More

Trevisan Machine Tool is the perfect choice if you’re looking for a reputable specialty machine builder to create a unique solution for your production application. To get more information about how our customizable Modulo Equipe and other special-purpose machine tools can benefit your business, our experts can guide you. Contact us online today to get started.