Multi-Turret Turning

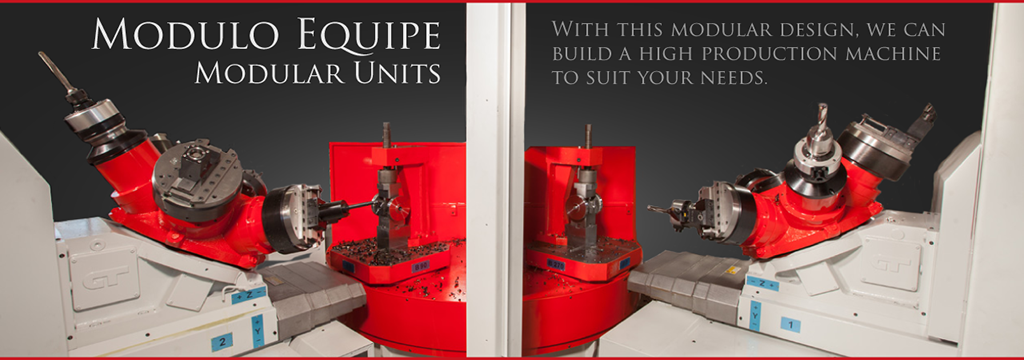

Modulo Equipe from Trevisan Machine Tool is a custom multitasking turning center that can significantly enhance a turning operation’s capabilities. Multiple turrets act as rotating assemblies that hold the cutting tools and position themselves independently, allowing for simultaneous machining with different tools.

At Trevisan Machine Tool, we pride ourselves on creating solutions that fit your needs. Modulo Equipe units enable us to design a machine specifically for your product by outfitting it with multiple turrets to work on one part simultaneously or step-by-step, allowing you to increase your production output.

Modulo Equipe by Trevisan Machine Tool

With up to six turrets on a modular unit, each spindle is customizable to do multiple operations without switching. A complete multi-turret machine could drill, contour, bore, rough, mill, face, turn and finish your product in just a fraction of the time other conventional equipment would take.

Combine two, three or more Module Equipe units to work on each end of the workpiece simultaneously to complete the job faster. These setups are ideal for axle ends, valves, cylindrical components and similar parts that allow each unit to operate without bumping into each other.

Set up multiple units around a multi-pallet rotating table or conveyor system with one loading station. Each modular unit will contain the cutting tools for that specific operation. This configuration allows you to customize tools to decrease cycle time. These machines can work on multiple parts simultaneously, reducing the cycle time even more.

These Modular Equipe turrets can even be combined with our horizontal machining center spindles for even more flexibility and production.

Benefits of Choosing Trevisan for Multi-Turret Turning Centers

Implementing Modulo Equipe modular units from Trevisan Machine Tool into your turning operation allows you to experience advantages over traditional twin-turret lathes, including:

- Increased productivity: Multi-turret turning units enable simultaneous machining operations, reducing cycle times and increasing overall productivity. Different tools can perform separate functions on the part at the same time, including turning, milling, drilling and boring.

- Improved versatility: Multitasking turning centers with multiple tool turrets offer enhanced versatility over conventional machinery by producing complex parts with various features, performing several operations simultaneously and reducing the need for additional machine setups.

- Enhanced accuracy and precision: By utilizing multiple tools at once, multi-turret turning units provide better accuracy and precision in machining. They can complete many tasks, reducing cumulative errors that can occur in equipment requiring multiple cycles.

All these benefits help machining operations save valuable time and money while eliminating potential bottlenecks in production.

Contact Us (sidebar)

"*" indicates required fields

CELL MACHINE -

SINGLE STATION, MULTIPLE UNITS

Combine 2, 3, or more Module Equipe units to work on each end of the part simultaneously to get the job done faster. This is ideal for parts such as Axle ends and axle ends that allow each unit to operate without bumping into each other.

TRANSFER MACHINE -

MULTIPLE STATIONS, MULTIPLE UNITS

Set up multiple units around a multi-pallet rotating table or conveyor system. The machine will also have one loading station. Each unit will be equipped with the cutting tools for that specific operation. This allows you to customize tools to decrease cycle time. These machines can work on multiple parts simultaneously decreasing the cycle time even more.

Contact the Experts at Trevisan Machine Tool Today for More Information

The experts at Trevisan Machine Tool can help assess your unique machining application to determine the most efficient and productive multi-turret configuration for your production needs. Since 1963, we have a proven track record of providing customers across the industry with solutions to their most complex machining challenges. Contact the Trevisan team online today for a quote or to obtain additional technical specifications.